TO`G`RI OQIMLI TOLA AJRATGICH ISHCHI DETALLARINI OPTIMALLASHTIRISH.

THE INFLUENCE OF SAWN SEED TARAGO ON THE CHARACTERISTICS OF RAW MATERIALS

Ergashov Yu Urishev M.M

Fergana Polytechnic Institute

yuldashaliergashov@gmail.com urishevmurodjon3@gmail.com.

Annotation: In this article, the output characteristics of defibered seeds from the working chamber of a saw were studied, and the influence of factors affecting the characteristics of seed output was analyzed.

Key words: Working chamber, peshtak burs, saw cylinder, colosniks, lower apron, front apron.

In the field of primary processing of cotton, changes are taking place in the following years according to the demands of the times, new techniques and technologies are being introduced, and cost reduction is being carried out with the production of more and high-quality fiber in the primary processing of cotton. In recent years, increasing the efficiency of cotton-textile clusters, increasing the capacity of deep processing of cotton raw materials, their modernization and technical re-equipment, increasing their profitability through the wide introduction of scientifically based methods and intensive technologies to this process, high considerable work has been done in terms of production of finished products with added value and creation of new jobs.

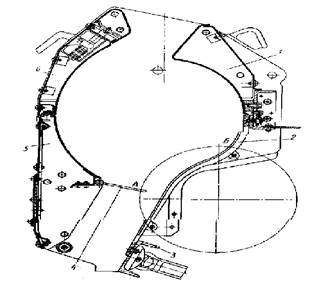

The working chamber is the main part of the gins, it includes the factors affecting the quality indicators of the fiber and the seed while preserving the natural properties of the fiber during the ginning technological process. The working chamber of the gin is composed of the following main details. , It consists of fixed colosniks 2, lower colosnik turn 3, seed comb 4, lower apron 5, and front apron 6.[1]

Figure 1. Working chamber of the chainsaw demon.

1- previous scholarship; 2-Consolidated colons; 3-Lower colosnik turn; 4-seed comb; 5-lower apron; 6-front apron;

The stable operation of the working chamber ensures the full operation of the ginning technological processes. The stable operation of the working chamber of the gin can be ensured by increasing the mass of seeded cotton in the chamber or by reducing the average time of fiber and seed staying in the chamber, which in itself is a worker. The hairiness of the seeds coming out of the chamber depends on the density of the cotton raw material and the structure of the seed comb.[2]

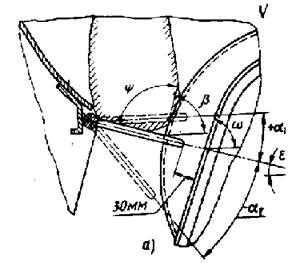

Fig. 2. Schematic diagram of the location of the seed comb.

Analyzing the actions that take place in the working chamber, the settling and expansion of the raw material in the part of the seed comb ensures the free release of seeds.

The amount of raw material sinking is adjusted by the deviation angle of the seed comb a1. The change of a1 changes the elevation angle of the raw material shaft b and the angle of meeting the raw material shaft with the saw cylinder. As a result of the increase in the angle of inclination of the seed comb a1, the increase in the subsidence and expansion of the raw material shaft creates the conditions for the free release of the seeds. But the increase of the angle a1 leads to the increase of the angle b and the reduction of the angle φ. In this case, the resistance to the movement of raw materials increases.[3]

It is allowed to change the angle a1 of the current genie constructions from +15 0 to -400 in relation to the angle e1 in the middle state of the seed comb. The angle of the middle position of the seed comb is defined as eo`r= 90 according to the expression below. The angle of exit of the seeds ω, the angle a1 of the columns depends on the curved surface of the columns. The angle ωmin>p ( p - the angle of friction of the seeds on the colossal surface) . We accept this expression, taking into account the fact that the weight resists the movement of raw materials to ensure the guaranteed release of seeds:

ωmin ̴̰ (2,6 ÷2,8) p

For cast iron surfaces:

P= 24 ÷25

It can be seen from the expressions given above that the output of seeds in the working chamber depends on the movement of the raw material roller and the state of installation of the seed comb. However, the characteristics of the raw material roller are variable depending on the type of selection. ``siri is also considered the main factor.[4]

To sum up, today the issue of reducing the obstacles that affect the emergence of seeds as much as possible is one of the most urgent issues of today.

Based on the characteristics of the raw material, it was found that by reducing the time of the seed in the working chamber, it is possible to increase the efficiency of the working chamber of sawing machines.

References.

[1] Yu. Ergashev, A. Sh. Khusanova, M. Babayeva. Analysis of dynamic characteristics of selective technology of sawing // FarPI Scientific-Technical Journal-Fergana 2020 №1 B.252-2555

[2] A. Sh. Khusanova. Optimization of geometric dimensions of ginning elements of selective technologies // FarPI "Journal of Scientific Technology" Issue 4. "Optimization of geometric dimensions of ginning elements of selective technologies" Fergana-2020 P.158-160

[3] A. Salimov, Sh. A. Khusanova. Analysis of experience in the introduction of modern information and communication technologies in ginneries. Republican scientific-technical conference International scientific-educational electronic journal. No. A3-21.10.2020.

[4] A. Salimov, O. Salimov, Sh. Khusanova, I. Khakimov "The problems of natural fiber and textile materials on fire resistance" Saarj journal Akademicia: an international multidisciplinary research journal April-2020. https://saarj. com/wp-content/uploads/special-issue/2020/ACADEMICIA-JULY-2020-SPECIAL-ISSUE.pdf

[5] O. Sh. Sarimsakov, N. M. Sattoriv, Z. A. Siddikov, Sh. A. Khusanova. Improvement of the Process in Disassembling of Cotton Stack and Transferring the Cotton into Pneumotransport// International Journal of Advanced Science and Technology Vol. 29, No. 7, (2020), pp. 10849-10857

[6] Yu. Ergashev, A. Sh. Khusanova, O. Sh. Sarimsakov, Kh. Turdiyev, J. Oripov. Selective technologies of sawing Fergana Polytechnic Institute "Selective technologies of sawing madness" "Classic" publishing house-2020 ISBN: 978-9943-6662-7-6.

Скачано с www.znanio.ru

© ООО «Знанио»

С вами с 2009 года.

![]()