1

2

|

|

|

|

DOI:10.5958/2278-4853.2021.00737.0

IMPROVEMENT OF TECHNOLOGY TECHNOLOGY

MANUFACTURING WOOD, WOOD WITH SULFUR SOLUTION

Zarnigor Alisher qizi Mirzaeva*

*Fergana Polytechnic Institute,

Fergana, UZBEKISTAN

Email id: z.mirzayeva@ferpi.uz

The article provides practical recommendations for improving the technology of modifying poplar wood with sulfur solution used in construction practice. The parameters of the optimal mode of organizing the process in the hot-cold bathing method have been developed. In the Republic of Uzbekistan, there is a shortage of wood raw materials used in construction. It is known that coniferous timber (high strength) is grown mainly in the forests of Russia, due to the small number of forests in our country and the growth of only logs from local timber (Mirzaterak, California logs), as well as their low durability. If we take into account the rapid growth of poplar, it will be possible to increase the durability of this type of wood and their wide spread use in infrastructure facilities.

KEYWORDS: poplar wood, sulfur solution, impregnation rate, temperature-time regime, humidity, energy intensity, porosity, strength.

In the Republic of Uzbekistan, there is a shortage of wood raw materials used in construction. It is known that coniferous timber (high strength) is grown mainly in the forests of Russia, due to the small number of forests in our country and the growth of only logs from local timber (Mirzaterak, California logs), as well as their low durability. If we take into account the rapid growth of poplar, it will be possible to increase the durability of this type of wood and their widespread use in infrastructure facilities.

Although building codes and regulations provide for the protection of wood, many woodworking enterprises produce wood products and structures without protecting (soaking) the wood, resulting in them becoming unusable without much work. [1-21] This requires the implementation of immediate protection of wood technology, which leads to the need to modify them.

It is necessary to improve the technology of soaking the logs with sulfur solution, ie the optimization of the soaking regime and the technological process of soaking. 2. Methods for optimizing the mode of impregnation of wood in sulfur solution:

There are several ways to optimize the mode of soaking wood

(logs) in a solution of sulfur. In the first method, the moisture content of

the wood, the initial temperature of the solution and the duration of

impregnation are taken as the factors influencing the degree of absorption of

the sulfur solution into the wood, in the second method the porosity of the

wood, the cooling rate of the boiling solution and the temperature drop.

There are several ways to optimize the mode of soaking wood

(logs) in a solution of sulfur. In the first method, the moisture content of

the wood, the initial temperature of the solution and the duration of

impregnation are taken as the factors influencing the degree of absorption of

the sulfur solution into the wood, in the second method the porosity of the

wood, the cooling rate of the boiling solution and the temperature drop.

Comparing the known methods of soaking wood with each other, the best method is to soak in a "hot-cold" bath.

The main factors influencing the absorption of sulfur solution into wood are:

- Duration of heating wood in a "hot" bath

- Duration of cooling of the sulfur solution

- The duration of storage of wood in the "cold" bath.

The studies used mathematical modeling methods to optimize the parameters of the wood impregnation process in sulfur solution and multifactor optimization methods of 23 types of experiments. The use of such a method allows to take into account the impact of all factors, as well as to reduce the number of experiments and qualitative assessment of the degree of soaking, to determine the optimal method of soaking.

Three factors were varied to optimize the soaking regime; X1 - duration of heating wood in a hot bath, min; X2 - duration of cooling the solution temperature in a cold bath, min; X3 - duration of soaking wood in a cold bath, min;

Factor variation intervals and levels are based on the data given in the norms.

The numerical values of the mathematical planning factors of the experiment are given in Table 1.

TABLE-1

Sign of factors

№ Factors

Х1 Х2 Х3

1. Variation interval 15 10 30

2. Basic level 45 30 50

3. High level 60 40 80

4. Low level 30 20 20

The temperature of the "hot" bath was set at 1600C, at which point the sulfur chain breaks and the solution has the lowest viscosity, and reptile chains are formed. This makes it easier for vapors to escape from the wood's pores, allowing the sulfur solution to seep into the wood's fibrils. The temperature of the cold bath is set at 1200C, which leads to more damage to the

|

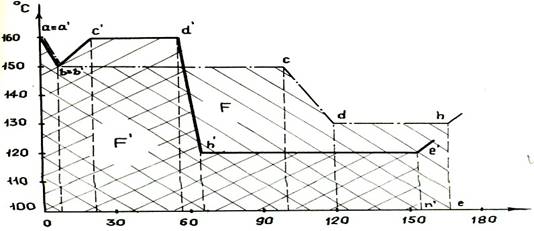

wooden capillaries due to the difference in temperature of hot-cold baths, which in turn plays a key role in the adopted method of dipping. 3. ANALYSIS OF EXPERIMENTS. Analysis of the results shows that the degree of absorption of sulfur solution in wood has the greatest effect on the duration of soaking wood in a cold bath. The minus (-) signs in front of the coefficients are directly proportional to the rate of sulfur absorption for factors X1 and X2, the rate of heating of the wood in a hot bath, and the rate of cooling of the solution to the temperature of the cold bath. This confirms the theoretical research on the impregnation of porous materials in solution. According to the results obtained, the parameters of the optimal mode of the process of soaking wood in a solution of sulfur in a hot-cold bath are as follows: - Duration of heating wood in a hot bath - 30-35 minutes; - Cooling time of the solution - 5-10 minutes; - Duration of soaking in a cold bath - 80 - 90 min. Let's compare the optimal mode of spraying terracotta with other deciduous trees. To do this, we take a mountain whose anatomical structure, that is, its micro- and macrostructure, is close to it. For comparison, we accept the process of soaking the sheets in a solution of sulfur. Here, too, this process is carried out by the method of hot-cold baths, the results of which are performed graphically and are shown in Figure 1. The temperature-time soaking mode of the compared variants consists of the following sections. (Figure 1.) аb, а1b1 – the area ofa sharp drop in temperature as a result of bathing wood in a hot bath; Bс, с1d1- wood soaking area in a hot bath: сd, d1h1- - temperature difference of sulfur solution; DH, h1e1 -- a plot of soaking wood in a cold bath b1с1- the site of heating the sulfur solution to the initial temperature of the hot bath; |

Picture. 1. Temperature time mode of soaking in a solution of sulfur - and poplar; The main indicator for comparison was the amount of energy required to soak the wood

|

in a 1% solution of sulfur, or to increase the soaking rate of the wood by 1%. If the conditional energy is the same as the surface (F) of the polygon "absdhe" for a log, then for |

|

|

|

в1 с1d1 h1e1n1and (F'1), which are bounded by the broken coordinate axes and showed the |

|

broken |

lines of the immersion process. |

|

The nu For To F

|

merical quantities of these surfaces are as follows; gterak: Пiti,grad.х.min . togterak Пiti,grad.х.min .

Pi is the duration of the soaking mode section, min; if we take the ratio of the numerical quantity of these surfaces to the degree of soaking, then efficiency of the soaking process is obtained. For Togterak F

forterak F

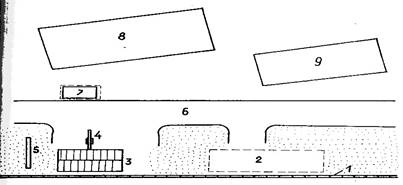

It can be seen that the energy consumption of soaking a poplar in a sulfur solution is lower than that of a poplar under the same conditions, or that the conditional amount of energy required soaking a poplar in 1% sulfur solution is 1.6 times less. This indicates the abundance of pores in the macro and microstructure of the poplar and the development of permeable tubes. (compared to porous pores) 10 - 20% more, it is clear that soaking poplars in a solution of sulfur is somewhat more effective than soaking poplars, but the effectiveness of soaking poplars is not only due to the large porosity of poplars (1.1 - 1.2 times) also depends on the physicochemical effects. several years of experience, many authors have developed a scheme of the technological process (plot) for soaking wood in sulfur solution, based on research; we will give a brief description of these schemes. The general plan of the site is shown in Figure 2. The technological process of soaking is carried out as follows: the sulfur solution is filled into 4 baths, taking into account the amount of wood to be soaked from 7 concrete pools (the solution in the bath in which the wood is lowered should not drip). Then the electric heaters are turned on and the solution temperature rises to the required level. (1550 - 1600 for "hot" bath; 1200S – grad for "cold" bath). The electrification devices are then disconnected from the power supply, and the prepared 2 wooden packages are fastened to the container and tested in a “hot” bath with a special load.After holding the wood in a hot bath for 30-40 minutes, 7 pumps are |

|

Where: ti-- the Based on 130 |

|

|

started and the hot sulfur solution is pumped into the "cold" chamber, which does not mix with the "cold" solution, because the density of "hot" sulfur is 1.77-1.78 t / m3, 120 - Density of cold solution 130grad 1.8 - 1.81 t / m3. Thus, a layer of "hot" solution is formed on the surface of the cold solution, which creates a hydrostatic pressure, and after 10-15 minutes the difference in hydrostatic pressure is felt due to the height of the solution. |

|

|

|

|

|

|

|

|

Picture. 2. General plan of the area of wood impregnation in sulfur solution; 1 - reinforced concrete container; 2 - storage area for wooden parts; 3 - terrace over the bath; 4 - cantilever monorails for trolleys; 5 - fire shield; 6 - asphalt road; 7 - concrete pool for sulfur storage; 8.9 - Auxiliary buildings. Then a 6-gauge faucet located on the curtain wall with thermal insulation is opened and a sulfur solution with a temperature i 120 - 1300S flows into the chamber where the wooden parts are. The pump 7 runs for 50-60 minutes until the solution passes into the chamber, then the shut-off valve is closed. Originally soaked in "hot" temperature, the wooden packages now have a temperature of 120 - 1300S / h, which corresponds to the recommendations determined experimentally [6]. The duration of soaking wood products in a cold chamber is 0.5 - 1.5 hours, depending on the degree of soaking the wood in sulfur solution. At this time, the solution temperature in the hot chamber is 150 – 160grad C, in which new wooden packages can be placed. (20 to 30 minutes before removing the wooden packages from the cold chamber) [6-21]. The shelf life of wooden packages in "hot" and "cold" chambers may vary slightly depending on the type of wood and its humidity. If it takes a total of 145 minutes to soak the logs, this time is 120 minutes for the logs, with both types of wood absorbing the same amount of sulfur solution. In terms of mass, the percentage of soaking of poplar wood is higher than that of log (196% poplar and 140% log) because the structure of the poplar is relatively porous. If a two-chamber bath is used effectively, the duration of the wood soaking cycle is 90 minutes when the new package is loaded after a maximum of 30 minutes and when the wood is loaded after soaking. Wood soaking efficiency is up to 3 times higher, and the soaking quality of wood is also improved. 4. CONCLUSION |

|

Modification of poplar wood with sulfur solution in this way allows to improve the quality of structural poplar wood, improve the performance of wooden structures made of it and increase the service life.

LIST OF USED LITERATURE:

1. Khrulev V.M., Arislanov O.N. Technology skleivaniya modifitsirovannoy drevesiny. Review infrom. M. VNIPIEIlesprom, 1984. p.36.

2. Khrulev V.M., Gorbulev V.A., Kondrashov S.M., Bekbolotov J.B. Prochnost i vodostoykost drevesiny, propitannoy seroy. Izv. Vuzov, Stroitelstvo i arhitektura, Novosibirsk, 1985. №8. s. 72 - 76.

3. Khrulev V.M., Kondrashov S.M., Bekboltov J.B. Skleivanie drevesiny, propitannoy seroy. Osnovanie napravleniya uskoreniya nauchno - tehnicheskogo progressa v derevoobrabatыvayushchey promыsh-lennosti. Thesis dokl. Respubl. Nauchn. Conf. Kiev, 1986. p. 135.

4. Antikorrozionnaya zashchita seroy stroitelnyx izdeliy iz betona i drevesiny /. V.M. Xrulev, V.V. Goretyy, V.G. Gazamatov. - Alma - Ata: KazNIINTI, 1988 - p. 50.

5. Goncharova N. I., Abobakirova Z. A., Kimsanov Z. Technological Features of Magnetic

Activation of Cement Paste "Advanced Research in Science // Engineering and Technology. - 2019. - T. 6. - №. 5.

6. Goncharova N. I., Abobakirova Z. A. RECEPTION MIXED KNITTING WITH

MICROADDITIVE AND GELPOLIMER THE ADDITIVE //Scientific-technical journal. –

2021. – Т. 4. – №. 2. – С. 87-91

7. 7.Goncharova N. I., Abobakirova Z. A., Mukhamedzanov A. R. Capillary permeability of concrete in salt media in dry hot climate //AIP Conference Proceedings. – AIP Publishing LLC, 2020. – Т. 2281. – №. 1. – С. 020028.

8. Goncharova N. I., Abobakirova Z. A. RECEPTION MIXED KNITTING WITH

MICROADDITIVE AND GELPOLIMER THE ADDITIVE //Scientific-technical journal. –

2021. – Т. 4. – №. 2. – С. 87-91.

9. Asrorovna A. Z. Effects Of A Dry Hot Climate And Salt Aggression On The Permeability Of Concrete //The American Journal of Engineering and Technology. – 2021. – Т. 3. – №. 06. – С. 6-10.

10. Goncharova N. I., Abobakirova Z. A., Mukhamedzanov A. R. Capillary permeability of concrete in salt media in dry hot climate //AIP Conference Proceedings. – AIP Publishing LLC, 2020. – Т. 2281. – №. 1. – С. 020028.

11. Abobakirova Z. A. Regulation Of The Resistance Of Cement Concrete With Polymer

Additive And Activated Liquid Medium //The American Journal of Applied sciences. – 2021. – Т. 3. – №. 04. – С. 172-177.

12. Goncharova N. I., Abоbakirova Z. A., Kimsanov Z. Technological Features of Magnetic

Activation of Cement Paste" Advanced Research in Science //Engineering and Technology. – 2019. – Т. 6. – №. 5.

13. Mirzazhonovich G. G., Ogly AUA, Ogly H. A. M. Influence of hydrophobizing additives on the thermophysical properties and long life of expanded clay concrete in an aggressive environment / / American Journal of Engineering and Technology. - 2020. - Vol. 2. - no. 11. - pp. 101-107.

14. Davlyatov S. M., Makhsudov B. A. Technologies for producing high-strength gypsum from gypsum-containing wastes of sulfur production-flotation tailings //ACADEMICIA: An International Multidisciplinary Research Journal. – 2020. – Т. 10. – №. 10. – С. 724-728.

15. Akhrarovich A. X., Mamajonovich M. Y., Abdugofurovich U. S. Development Of Deformations In The Reinforcement Of Beams With Composite Reinforcement //The American Journal of Applied sciences. – 2021. – Т. 3. – №. 5. – С. 196-202.

16. Muratovich D. S., Shavkatovich N. K. Influence of Changes in Microclimate Parameters on Human Well-Being and Operational Characteristics of Building Structures //The American Journal of Engineering and Technology. – 2020. – Т. 2. – №. 11. – С. 113-117.

17. Abdukhalimjohnovna M. U. Technology Of Elimination Damage And Deformation In

Construction Structures //The American Journal of Applied sciences. – 2021. – Т. 3. – №. 5. – С. 224-228.

18. Mirzaakbarovna M. S. Wood Drying In Construction //The American Journal of Applied sciences. – 2021. – Т. 3. – №. 5. – С. 229-233.

19. Mirzaakbarovna M. S., Sultanbayevich T. N. Wood Processing For Construction //The American Journal of Applied sciences. – 2021. – Т. 3. – №. 5. – С. 186-189.

20. Arabboyevna, A. M. (2020). In Orthophotoplane Technology Photomod Mosaic Module. International Journal Of Discourse On Innovation, Integration And Education, 1(4), 93-97.

21. Abdukadirova, M. A., & Mirzakarimova, G. M. (2020). Value of geodetic works in construction of hydrotechnical structures. ACADEMICIA: An International

Multidisciplinary Research Journal, 10(6), 1307-1312.

733

Материалы на данной страницы взяты из открытых источников либо размещены пользователем в соответствии с договором-офертой сайта. Вы можете сообщить о нарушении.