MINISTRY OF HIGHER AND SECONDARY SPECIAL

EDUCATION OF THE REPUBLIC OF UZBEKISTAN

Bukhara engineering technical institute

SH.KH.SAMIEVA , K.I. MUSTAFOEV

INNOVATION TECHNOLOGIES IN THE SEWING

INDUSTRY

2020

MINISTRY OF HIGHER AND SECONDARY SPECIAL EDUCATION OF THE REPUBLIC OF UZBEKISTAN

Bukhara engineering technical institute

SH.KH.SAMIEVA, K.I. MUSTAFOEV

THE SEWING INDUSTRY

for students studying in the direction

5321600 - “Technology and equipment for light industry”

2020

Samieva, Sh.Kh. , Mustafoev, K.I.

Innovation technologies in the clothing industry. Textbook for students of the direction 5321600 "Technologies and equipment of light industry" / Sh.Kh. Samieva, K.I. Mustafoev

Ministry of Higher and Secondary Special Education of the Republic of

Uzbekistan. Bukhara engineering technical institute

Reviewers:

Kh.K. Rakhmonov- Bukhara Engineering and Technology Institute

Doctor of Technical Sciences , Professor of the Department

"Machinery and equipment for light industry"

N. Nurova - Director of Bukhara Oceanlyuks LLC

The textbook “Innovation technologies in the clothing industry” includes a description of a list of topics that characterize current contemporary areas of innovation in the clothing industry. The content of each topic reveals the basic concepts, definitions, keywords and semantic points. The structure and content of the chapters comply with the requirements of the State educational standard and the basic competencies of bachelors in the direction 5321600 "Technologies and equipment of light industry". The chapters reflect the relevance of these areas to improve the efficiency of production processes, as well as formulate the tasks of increasing the level of training of specialists taking into account the requirements of employers and the needs of modern production of the country, the latest achievements in science and practice of light industry.

The processes of training qualified personnel in the field of higher education

are developed on the basis of modern pedagogical

technologies, innovation educational projects and a radical improvement in the quality of training of competitive specialists based on the adaptation of national qualification requirements of countries to international standards. The experience of foreign prestigious educational institutions such as the University of the West of England (England), Curtin University (Australia), Emily Carr University of Art and Design (Canada), Art Center Colleje of Design (USA ) can serve as examples of the formation of professional competencies. ) engaged in priority pedagogical research aimed at developing a creative, aesthetic worldview of students by creating design and applied works of art based on the modernization of the content of professional education.

The training of highly qualified specialists in accordance with international standards is largely associated with the sustainable development of higher education and the systematic training of national personnel. This, in turn, requires constant improvement of the content of the educational process, its implementation through the creation and implementation of advanced pedagogical and teaching technologies based on the achievements of information and communication technologies, analytical studies of the requirements of a market economy and the consideration of national cultural and historical traditions. Such a task is relevant for the development of an innovation worldview, which is an important part of educating a harmoniously developed personality in the process of preparing future specialists, studying its pedagogical aspects and bringing education to a new qualitative level.

In our country, to implement this direction, much attention is paid in all areas: science, art, literature and education . The Development Strategy of the Republic of Uzbekistan in 2017-2021 provides for the priority task formulated in the Decree of the President of the Republic of Uzbekistan . It consists of “continuing the policy of improving the continuing education system, improving the quality of educational services and continuing to train highly qualified personnel in accordance with modern requirements of the labor market ”[1] [] . This will allow our country to successfully develop in the future and become a roadmap for reform over the next five years. Improving the innovation worldview is an important problem for the implementation of tasks in the study of special subjects in the direction of “Technology and equipment of light industry” in higher education institutions.

This textbook , to a certain extent , contribute to the implementation of the tasks set out in the Decree ah President of the Republic of Uzbekistan : number UP-4947ot February 7, 2017 "On the strategy of further development of the Republic of Uzbekistan», № P P - 2909 "On measures for further development of the higher education system ”Dated April 20, 2017, No. PP-3160“ On increasing the effectiveness of spiritual and educational work and increasing the development of the industry to a new level ”dated July 28, 2017, No. UP-5264“ On the establishment of the Ministry of innovation Development of the Republic of Uzbekistan ”dated November 29, 2017 year and, number UP-5313 "On measures on radical improvement of the system of general secondary and secondary special education" on 25 January 2018, number P P- 3775 on June 5, 2018 "On additional measures for the radical improvement of the quality of education in higher education and their active participation in comprehensive reforms of the country ”, as well as other regulatory documents related to this area.

The terms "innovation", "innovation", "high technology", "high technology products" and others today have taken a strong place both in the vocabulary of scientists, specialists, and among business people, entrepreneurs and have recently gained some halo of popularity. In fairness, it should be noted that “innovation” is not a phenomenon of perestroika or reform. This type of activity has existed since the inception of civilization, and it was he who determined the actual progress in the development of mankind, since it led not only to an increase in the standard of living, but to an improvement in its quality. The first innovation managers also appeared at the dawn of civilization, only they were called differently . Innovation activity is characterized by continuous qualitative improvement of manufactured goods and services, promotion (or, as they say by tradition, implementation) of new technologies, new types of products and services in production and on the market. Innovators are the most active part of society. These are scientists, specialists and inventors creating new designs, machines, devices, materials, etc. The development of new technologies, the introduction of new ideas, inventions, and the so-called "know-how", in a word , the creation of innovations is a special type of business that has its own characteristics, features and problems, regardless of which particular industry it is in going on. Innovation activity is the process of creating a new product, new technology or service based on the results of scientific research in order to obtain competitive advantages in the sale of products, works and services in the markets.

The transition to a new stage of scientific and technological development required the strengthening of innovation activity and a new approach to innovation. In modern conditions, the enterprise requires the ability to develop and implement an effective innovation policy based on its own capabilities and internal potential, as an essential condition for survival and successful functioning in a constantly changing competitive environment. The current stage of development of the economic situation in the country is characterized by processes requiring the adoption of a large number of investment decisions. innovation processes, their implementation in new products and technologies is the basis of economic development. The innovation process is the preparation and implementation of innovation changes and consists of interconnected phases that form a single whole. The theory of innovation processes is quite well developed by both domestic and foreign researchers. The publications of such authors as Drucker P., Martino J., Santo B., Porter M., Twiss B., Schumpeter I. Anchishkina A. I., Arkhangelsky V. N., Blyakhman L. S., Vasiliev G A., Volkova I.M., Glazyeva S. Yu., Dagaeva A.A., Duzhenkova V.I., Oleinikova E.A. and others. The educational publication “innovation Technologies in the Garment Industry” meets the modern requirements of training specialists in the field of innovation development. As a result has mastered eniya educational material of the textbook the student must acquire new knowledge about the basic concepts , related to innovation in the apparel industry; systemic understanding of innovation design methods and evaluating the effectiveness of innovations; as well as working skills as part of an innovation design team.

I SECTION. TRENDS AND INNOVATIONS IN THE FIELD OF SEWING

Innovation distinguishes leader from catching up

Steve Jobs Introductory phrase - an integrated approach, innovation at every stage of the

1.1. Innovations in the preparatory - cutting processes of sewing production A little about the preparatory production - digitalization, material databases, configuration, automation of storage processes, transportation of materials.

1.1.1. Description of cutting methods

When cutting fabrics, the material can be cut in various ways. Distinguish between mechanical , thermophysical and thermomechanical methods of cutting sewing materials . By mechanical methods are simple, complex, double and combined . The most common in the clothing industry are sawing, cutting with scissors and a combined method.

A simple mechanical cutting method is mainly used when cutting hard materials, for example, leather products, using one of the following methods: cutting, a knife, and also roller or rotary.

With the rink method, one sheet is cut. The contour of the parts is repeated by cutters (knives) mounted on the surface of the table. The roller, pressing material to the knives, cuts out the details.

In the case of rotary cutting, the material passes between two rollers, on one of which cutters are mounted.

When cutting by stamping, the cutting of parts is performed on the press: the cutters are fixed on the punch or matrix of the press. This method is expensive in conditions of frequent model interchangeability, since when switching to other sizes or design solutions, a complex alteration of the torch design is required.

A simple mechanical cutting method , performed by drilling, milling, stamping, is not widely used in the clothing industry.

Special methods for cutting sewing materials include electrospark, ultrasound, laser beam, microplasma arc, and jet monitor.

When cutting with ultrasound, a special apparatus is used, which carries out the cutting of the material with a vibrating tool operating in the range of sound or ultrasonic frequencies, interacting with the support.

The cutting of the material by the electrospark method is carried out along the line deposited by graphite on the upper flooring sheet; Electrodes are connected to its beginning and end and a high voltage current is supplied, under the influence of which the material is destroyed along the contour of the graphite line.

Laser beam cutting is based on the thermal action of the beam on the tissue, in which tissue is burned along the line of the beam. The principle of operation of lasers (converters of one type of energy into monochromatic coherent radiation of electromagnetic waves) is based on the emission of coherent light fluxes from some substances that have previously been exposed to light and have accumulated part of the light energy absorbed by them. For cutting material, the radiation can be CO2 gas. An optical cutter moving along the deck cuts the material with a concentrated light beam.

When cutting material with a microplasma arc, the executive tool is a plasma torch focusing the plasma torch in a very small diameter, less than 1 mm. The plasma generator is a plasmatron. In contact with plasma, the tissue is burned along the line of passage of the plasma torch. To protect against ignition of the fabric, a protective gas is supplied to the cutting zone.

In the hydraulic monitoring method, the material is cut by a thin stream of water emerging from the torch nozzle at high speed.

Each specific innovation appears as a result of the scientific-production cycle (STC) and goes through certain stages of development - creation , development and dissemination. The process of creating, mastering and disseminating innovation is called the innovation process.

1.1.2. H astilo Meth and cutting machines of the new generation.

Modern automated machines and complexes allow performing operations of laying materials, controlling their quality and subsequent cutting in accordance with effective layouts of patterns. The manufacturer of innovation automatic equipment Bullmer offers a range of modular flooring machines E100 - E400 for the clothing industry . On the basis of the material rolls guided by the rods in the form of a simple inexpensive construction , models with automatic installation of an air cushion and a rotating stand for unwinding the rolls and performing pairwise flooring are offered . Using the universally applicable fast (120 m / s) decking machine Compact E 600, which is equipped with a grooved tape for unwinding rolls of material, you can conveniently adjust the side guides of the rolls of materials, designed for a weight of 100 kg and a diameter of 500 mm from the serving side. The entire flooring process, including edge adjustment and material layout, is automatically controlled. This machine can be used for laying technical textile materials in a stack. Special equipment can be installed for rolls weighing up to 500 kg and a diameter of up to 1200 mm. Supporting rods without a conical bobbin are used for easy lifting of heavy rolls of materials . For cutting technical textile materials of all kinds, the Premiumcut II device has been developed , designed for individual layers and a small number of layers. Due to the variety and combinations of various tool tips, it meets the requirements of cutting a wide range of fabrics and flat materials. The main module of the cutting head with a tool holder for lifting, vibration with high frequency and rotation can be further expanded with round and band knives and punch, as well as a drill. It comes with a working width of 160–320 cm and a length of up to 12 m. Thanks to the integrated conveyor, continuous and overlapping flows of materials are possible (feeding, cutting, sorting). For continuous individual cutting, special feeding devices have been developed, for example, an automatic rolling device with a tray, including for heavy rolls, and an automatic unwinding device guided by rods, which delivers the material to the conveyor knife uniformly and without tension. Turbo.cut S cutting device with a stabbing knife, designed for cutting layers of materials of medium thickness (25 mm ). It is a productive and compact machine with a linear cutting speed of up to 90 m / min. and can be used in the clothing industry and for cutting leather.

Based on the proven design of the measuring machine, GerberTexnology has created small-series cutting machines equipped with a GTxL knife, which are designed for cutting layers of small thickness and can be used for cutting lines of various configurations and for all types of textile materials. The knife, operating at a speed of 46 m / min., Can be equipped with an automatic brush cleaning system, an InfoMark labeling system and an InVision system for matching patterns by cuts .

Company KurisSpecialmaschinenGmbH (Germany) presented its advanced flooring and cutting machines. Thus, the PionierSuperElectronic decking machine , thanks to the TFS device, provides the flooring without tension, both heavy and wrinkle-sensitive materials. Thanks to the constantly rotating rolls of materials and the contact area, a uniform flow of materials is ensured. Cutting occurs with the help of a patented unit for 0, 4sec. with a neat cut even on sensitive materials. Based on the existing series of equipment , improvements are proposed for TexCut cutting machines designed for different floor heights. For example, for the manufacture of garments in small batches, in the clothing industry and for cutting technical textile and special materials (aramid and glass fibers, combined materials, films), the TexCut 3001 was developed , which is used for cutting layers of small thickness thanks to a new design concept. In accordance with this concept, the replacement of knives is carried out within a few seconds due to the simple withdrawal of the cutting head in the service position.

1.1.3. Cutting equipment Bullmer (Germany).

Bullmer cutting machines are designed for single and multi-

layer cutting. For each type of material, taking into account its features, and for a variety of technical tasks, special cutting tools have been developed. Some cutting machines are designed to optimize speed if high throughput is required.

The standard equipment for all BULLMER cutting machines includes:

• Reversible pile conveyor

• Motion with linear modules along the X and Y axes

• Permanent magnet brushless drives for all axes

• Infinitely variable vacuum depending on parameters

• Vacuum Turbine Filter

• Built-in sound absorber for hoods

• Integrated pile cleaning

• Self-adjusting diamond blade sharpener

• Automatic dosing of oil supply depending on the frequency of operation of the knife

• Right side of the working side

• Industrial PC with real display, flat screen Built-in high-performance vacuum turbine, 15 kW Standard working width: 1600/1800/2000/2200 mm

• Standard cleaning zone length: 1850/2300 mm

Software:

• Windows operating system

• Operator Guide with Likelihood Check and Failure Diagnostics

• Automatic adaptation of the inclined position of the layers relative to the marker

• Automatic start point optimization for single pieces

• Exception of ordinary (general) cuts

• Automatic creation of a chain of markers (job queue)

• Test run - simulation of the cut path

• Resetting several markers in a job queue

• Optimize the cutting and cutting path of small pieces first

• Registration of operational data (data management)

• Remote Service Application

Figure 1.2 shows a high-performance cutting plotter. firm BULLMER.

Figure 1.2 . High Performance Cutting Plotter

BULLMER TURBOCUT

Its field of application is the manufacture of clothing and upholstery.

Serves small production series when high productivity is needed.

The material used is woven and non-woven materials for clothing and home textiles.

The special features of this innovative equipment are that thanks to the light beam and the aluminum profile construction combined with the TURBOCUT high-frequency knife, it has the fastest cutter in its category. Lightweight head allows you to develop acceleration of 1.3 g. The vertical high-frequency knife in TURBOCUT works with a cutting depth of up to 25 mm.

Additional benefits of the basic design:

• Cut window length about 1800 mm

• Screening conveyor with cleaning zone, approx. 1850 mm Optional equipment:

A camera can be mounted on the cutting head to support:

- matching jobs

- determining the reference point of the layers

Table 1.1 Technical Data in High Performance Cutting Plotter

BULLMER TURBOCUT

|

Working width: |

1600, 1800, 2000, 2200 mm |

|

Cut Window Length: |

about 1800 mm |

|

Length of sorting conveyor |

about 1850 mm |

|

Maximum positioning speed: |

100 m / min |

|

Max acceleration: |

1.3 g |

|

Positioning accuracy: |

0.1 mm |

|

Maximum cutting height (depending on material): |

Max. 25 mm |

|

Connections: |

|

PREMIUMCUT is a high-performance cutting plotter, which includes all the advantages that Bullmer equipment is characterized by - an excellent engineering solution, reliability and the highest versatility combined with low operating costs.

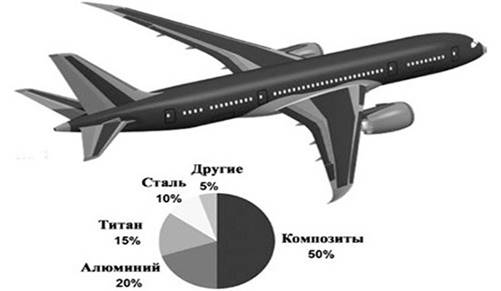

Range of application: Processing of technical fabrics and composite materials for the automotive industry, aircraft manufacturing and similar industries.

Bullmer

PREMIUMCUT ULS ultrasonic cutting plotter

Figure 1.1.4.

Materials used: Woven and non-woven technical materials, composite materials, sheet material, rubber, floor coverings and a wide range of synthetic materials. PREMIUMCUT cuts parts directly from a roll in any desired quantity. The material may be dense or wide; cut-out parts may have an irregular contour, may be small or large. PREMIUMCUT copes with all these difficulties. A large percentage of materials can be cut without using foil. PREMIUMCUT comes standard with a tool head equipped with one interchangeable cutting tool and pen. Depending on the type of head, up to 4 cutting tools and a pen can be controlled (in alternating order). Special tool combinations are available on request.

Working width: 1600 - 5000 mm; pitch 200 mm.

Standard Version :

• Linear modules and belt drives for X and Y axes

• Needle felt "endless" belt conveyor

• Transport system with clamps. The belt is fixed with clamps and guides to ensure alignment during feeding. Additional guide pulleys stabilize belt movement.

• Software with various functions

• Real-world industrial computer, flat screen TFT

• 7.5 kW vacuum pump

• Built-in hood sound absorber

• Built-in sort area

• Adjusting the tools with the spindle on the vernier (scale).

Optional delivery:

• Special belt conveyor for controlling an ultrasonic knife

• 15 kW double vacuum pump (2 x 7.5 kW)

• Pen for marking stitches and typing

• Sprayer for marking seams and printing

• Inkjet printer for annotating parts (before and after cutting)

• Projector (laser) for “cut part identification system”

• Monitor (TFT) for “cut part identification system”

• Foil unwinder

• Conveyor Cleaning Device

• Various software options

Consumer area: Manufacturers of lightweight and load-bearing structural components, for example, for aircraft construction, the automotive and railway industries, and their suppliers.

Materials used: Ultrasonic tools are used to process various materials:

- CFRP (carbon fiber)

- GRP (fiberglass)

- prefabricated fiber products

- composite plastics (prepregs)

- composite materials such as PVC (PVC), PES (polyester), PC (polycarbonate), PP (polypropylene).

Special Features: The ULS ultrasonic module is modular in design and is suitable for placement under the table, and when choosing additional tools. This means that the cutting system can be operated using ultrasonic technology and, in parallel, can be equipped with other cutting and processing tools.

Ultrasonic cutting is the technology of the future. The use of water jet and laser technology is not suitable for cutting CFRP, GRP and semi-finished fibrous products due to unwanted moisture or heat on the material being cut. This problem is solved by cutting tools with vibration caused by ultrasound. By this method, not only single-layer materials are cut in half, but also multilayer materials (up to 10 layers) into individual parts. Different blade geometries optimize the cutting result. Working width: 1600 - 5000 mm; pitch 200 mm. There are knives with different geometries.

1.1.4. Universal cutting systems (cutting plotters) iECHO.

IECHO universal cutting machines (cutting plotters) are an industrial digital automatic high-speed cutting system for use in various industrial sectors. This equipment can carry out through cutting, notching, milling, punching, marking and plotting with the highest accuracy. To provide maximum versatility for iECHO cutters, a wide range of tools is provided, including tangential knives, oscillating tools, rotary knives, creasing tools and milling cutters. IECHO cutting plotters, having made a real revolutionary breakthrough in digital cutting technology for a wide range of materials, occupy a leading position in the global market, pushing to the background brands that have been undeniable authorities for users for many years. IECHO demonstrates the most active sales dynamics and provides the market with the widest range of devices - from small format machines to industrial multi-layer plotters. High quality and reliability of iECHO plotters are provided by components of European and Japanese production. In China, the following is being carried out: development of the supporting structure, taking into account European trends in ergonomics and design, integrated assembly and technological verification of equipment. By guaranteeing consumers the high reliability of its products, iECHO provides a full 12-month warranty on all devices, unlike competitors, in which individual components are provided with a significantly shorter warranty period. An important advantage of iECHO cutting plotters is their unconditional maintainability. They can be repaired in detail - bearings, sensors, motors, etc. can be repaired without changing the entire assembly, unlike competitors' machines, in which, when one part fails, the entire module must be changed, which requires significant and completely unjustified users costs. Hardware and software demonstrate optimal consistency, which is a significant advantage of iECHO plotters.

Figure 1.1.5.

The iECHO universal cutting machines are represented by three series - BK, BK3 and TK3S.

• Indoor and outdoor advertising

Pattern cutting iECHO are the ideal solution for advertising and production companies. With their help, it is possible to carry out cutting of almost any materials used in the production of outdoor and interior advertising - cardboard, corrugated cardboard, foam board, films, banners, acrylic glass, PVC sheet, composite panels, corrugated and cellular plastics. These highly efficient machines significantly increase productivity and guarantee high quality finished products.

• Printing and packaging

Conventional punching machines used in the packaging industry make it possible to produce products in large batches with a minimum cost, but when producing “short” circulations, as well as in the manufacture of pilot samples of packaging products, the use of die-cutting machines becomes economically unjustified, since it requires manufacturing at the initial stage of production punching stamp and implementation of adjustment work. The iECHO complex makes it possible to simply and cost-effectively produce samples, single products and small batches of products and process not only ordinary cardboard, but also any other packaging materials - corrugated cardboard, monolithic and cellular polypropylene, PVC, etc. Packing lodges made of foam polyethylene can also be manufactured using iECHO equipment. The iECHO cutting system is characterized by high performance, allows you to execute orders on-line and in combination with specialized CAD systems is an indispensable solution for packaging factories. Machines for selective varnishing, as a rule, are much more expensive than machines for continuous coating. But it is possible to carry out selective varnishing with the help of continuous varnishing machines, if preliminary processing of the varnishing rubber is carried out on the iECHO cutter.

• Automotive and aircraft manufacturing, production of automotive accessories

IECHO cutting plotters can be successfully used for the production of car mats, seat covers, sun blinds, products for noise and heat insulation.

• Engineering and instrumentation

IECHO equipment is widely used in the production of high-precision gaskets and o-rings, in the manufacture of various machine parts, mechanisms, and devices. The iECHO complex is capable of cutting rubber, paronite, graphite, asbestos, oil-resistant fibrous paper, cable paper, asbestos paper, fluorinecontaining materials such as polytetrafluoroethylene (Teflon), synthetic and composite materials, and much more.

• Cut complex synthetic fabrics for a variety of tasks

The iECHO cutter allows you to replace traditional methods of cutting complex synthetic fabrics that require high labor costs and increase processing efficiency by at least 20 times. Using this device, it is possible to cut materials from carbon, aramid and fiberglass, as well as ultra-high molecular weight polyethylene with high accuracy. These features are widely used for the production of special professional equipment.

• Sporting goods

With the help of iECHO cutters, it is possible to cut non-metallic materials used in the manufacture of sports equipment - polyethylene for snowboards, materials based on carbon and fiberglass. iECHO is an optimal technological solution that will increase the speed of production of sports products and ensure consistent quality from batch to batch.

• Haberdashery and leather goods

IECHO cutting systems are an ideal tool for the haberdashery industry. It allows you to make patterns from materials such as genuine leather, PE, PP and EVA without the use of paper patterns. The cutter is successfully used in the manufacture of shoes, bags and suitcases, covers for documents and books, covers for mobile devices, folders, wallets and eyeglasses, etc.

• Clothing and textile products

The iECHO BK cutters are the perfect solution for the garment industry. It allows you to quickly draw any patterns when designing products, apply the necessary marking and carry out cutting fabrics, knitwear, leather and leather substitutes for sewing clothes, accessories, furniture upholstery. Management and control of all operations are carried out in real time using a special ERP system. The iECHO BK cutting plotter can also become an excellent assistant in training students of industrial educational institutions, who will be able to immediately learn how to use modern digital technologies in the process of mastering the profession.

Sawmakers iECHO BK

The sizes of the tables of the iECHO cutters of the BK series are 1300 x 1100 mm, 1700 x 1300 mm and 2500 x 1600 mm. This series of complexes is basic; All models of the series are equipped with a single-zone vacuum table with an acrylic worktop.

IECHO BK Series Saws are available with either one or two tool stations. The maximum cutting speed is 1 m / s, which is 2-4 times faster than manual cutting.

Sawmakers iECHO BK3 and TK3S

The sizes of tables of cutters iECHO of the BK3 series -

1700 x 1300 mm, 2500 x 1300 mm and 2500 x 1700 mm; TK3S series - 2500 x 1600 mm, 2500 x 2100 mm, 2500 x 3200 mm and 3500 x 2100 mm. Custom-made models with arbitrary table sizes can be made.

Unlike the VK series, these complexes are equipped with a multi-zone vacuum table with a top made of durable aircraft aluminum. The aluminum alloy on the surface of the honeycomb desktop, which is also used in the aerospace industry, guarantees geometric stability of the structure without dimensional changes due to thermal expansion / compression and minimal internal stresses. Mutually insulated dense cells of the honeycomb panel compensate for the load on the desktop, thereby ensuring the absolute flatness of the working surface even with its large size.

The iECHO Saws BK3 and TK3S Series come with two or three tool stations.

Servomotors Yaskawa (Japan) installed on the iECHO cutters of the BK3 and TK3S series allow cutting at speeds up to 1.5 m / s, which is 4-6 times faster than manual cutting and one and a half times in comparison with BK series machines . machines included a tool depth detection system (AKI). Complexes of the TK3S series, unlike BK and BK3, have a folding table design, which greatly simplifies their transportation.

On the ultra-wide portal of the TK3S series complexes, two engines with a balancing function are installed, which provide more stable and accurate portal movement. Complexes of the TK3S series, unlike the complexes of the BK and BK3 series, have a rack-and-pinion gear as a portal drive, which provides high speed, durability and excellent dynamics when cutting dense materials with extreme workload.

All models of cutting plotters can be equipped with an intelligent function of continuous cutting on the conveyor, which allows you to load materials continuously, efficiently perform extended tasks, process not only sheet but also rolled materials, reduce labor costs and increase productivity.

Operator Safety System (Safety Device)

All models are equipped with an effective protection system that ensures operator safety and eliminates the likelihood of injury during operation of the complex. In addition, four emergency stop buttons are installed on the iECHO cutters, when clicked, the machine stops working urgently.

Tool Depth Measurement System (AKI)

The AKI system automates the process of setting the immersion depth of a tool. With the help of this system, the immersion depth of the tool blades is quickly, easily and with high accuracy - a tangential knife, a Kiss cut knife, a circular knife. This ensures that the material is cut through without damaging the static substrate or conveyor belt. The AKI system is standard on the BK3 and TK3S systems.

All iECHO cutters are equipped with a high-precision automatic positioning system. Using the built-in CCD-camera provides the exact position of the tool and the possibility of contour cutting by reference marks. Due to this, you can avoid the errors that usually accompany manual operations, and take into account all the features of the cut out image.

When cutting fabrics, knitwear, non-woven materials, etc. with images printed on them, using reference marks to combine with cutting contours, due to the properties of these materials, is useless, since errors are inevitable. The Vision Cut system copes with this task perfectly.

When cutting materials such as genuine leather, it is important to place the contours of the cut so as to maximize the use of the material and minimize waste. In such cases, the HD projection system is used - a system that projects the contours of the cut on the surface of the workpiece, which helps the operator to accurately determine the position of the cut contours relative to the material.

The standard clearance of the cutter allows you to process materials up to 50 mm thick. Optionally increasing the clearance, you can cut materials up to 110 mm thick.

• Passive system. Roll materials are fed to the conveyor directly from the feed device, which is equipped with a material feed shaft, an additional shaft and a material tension mechanism.

• Active system. The system is synchronized with the conveyor system of the complex. It has a loop sensor and material edge control.

This system significantly saves working time and allows you to reduce the cost of products.

Installing a second portal

Complexes of the TK3S series with large desktop sizes can be equipped with two portals on request, which allows you to double productivity.

Cutting plotter (flatbed cutter) for automatic cutting of flooring iECHO GLS

![]() The iECHO GLS flatbed cutting

plotter is an excellent solution for automating the cutting area of a sewing

enterprise. Equipped with a high-speed electronic oscillating instrument and

intelligent control systems, the GLS plotter cuts any textile and soft materials

with high quality, precision and productivity. The iECHO cloud management

server has a powerful data conversion module that allows you to use the main

CAD software packages that exist on the market. The users are provided with

comprehensive professional technical support so that they can easily and

successfully switch from traditional methods of cutting materials to automatic

digital ones.

The iECHO GLS flatbed cutting

plotter is an excellent solution for automating the cutting area of a sewing

enterprise. Equipped with a high-speed electronic oscillating instrument and

intelligent control systems, the GLS plotter cuts any textile and soft materials

with high quality, precision and productivity. The iECHO cloud management

server has a powerful data conversion module that allows you to use the main

CAD software packages that exist on the market. The users are provided with

comprehensive professional technical support so that they can easily and

successfully switch from traditional methods of cutting materials to automatic

digital ones.

Features of the iECHO GLS plotter :

• The system of control and correction of tool movement to ensure the optimal cutting mode in accordance with the characteristics of the processed material.

Figure 1.1.6.

• Self-developed management server to simplify operation and achieve the best cutting quality.

• Modular solutions for individual user requirements.

• System of an automatic computer layout of a cut on a working surface.

• The function of automatic compensation of the sharpening of the blade in accordance with its wear to ensure constant accuracy of the cut.

• Tool cooling system that prevents overheating of the material and its adhesion.

• System of intellectual correction of material loading.

• Vacuum clip material with the ability to adjust the suction force.

• Automatic film-coating device to increase the efficiency of the vacuum clip and additional energy savings.

• Ease of management and maintenance.

• A table for collecting finished products.

• Long service life.

It is optionally possible to install:

• Guides under the cutter for installing 2 to 3 unwinding systems in order to increase productivity.

• Guides under the cutter for installation from 2 to 3 wide devices.

• Automatic decking device.

• Device for smoothing material from a cent to the edges.

Advantages of digital cutting technology relative to traditional cutting methods

• Significant increase in productivity.

• Improving the working environment.

• Optimization of production management.

• Rational use of materials.

• Higher quality material handling.

• Improving the credibility of the manufacturer.

Specifications for the iECHO GLK Plotter

Table 3

|

Maximum cutting depth |

75 mm (with active vacuum system) |

|

Maximum cutting speed |

200 mm / s |

|

Maximum acceleration |

0.3 g |

|

Width of the working table |

1.6 m / 2.0 m / 2.2 m (optional) |

|

Desktop Length |

1.8 m / 2.5 m (optional) |

|

Power supply |

Plotter - 1 phase: 220 V, 50 Hz Vacuum pump - 3 phases: 380 V, 50 Hz |

|

Power consumption |

Plotter - 4 kW Vacuum pump - 20 kW Average power consumption - 15 kW |

|

Interface |

Serial port |

|

terms of Use |

Temperature: 0 - 40 ° С, rel. humidity: 20 - 80% |

Help about iECHO.

Company Smart-T is an official partner iECHO - known manufacturer of CNC cutting equipment for small-scale and high-volume production, as well as a leading developer of specialized software systems and visual design.

Company Hangzhou iECHO Science Technology Co ,. Ltd. was founded in China in 1994. The company's solutions iECHO are very popular in the advertising, printing, packaging, textile and construction industries, as well as wind energy and aviation and automotive industries. For over 20 years, iECHO has been developing manufacturing solutions for world-renowned suppliers from general design, development of technologies for introducing several operations on one machine to the complete debugging of the automatic cutting process.

Company iECHO - a high-tech enterprise of state planning, located in

Zhejiang Province. The headquarters of the company is located in the National High-Tech Development Zone. The company has its own building with an area of about 4000 square meters, which houses marketing and service centers. The research and development center is located in the USA, in the state of Utah. For nearly 20 years of research and development, iECHO has received more than 20 national patents and registered 30 software copyrights, has taken part in many important programs of the National Ministry of Science and Technology.

Among iECHO operates a close-knit team of highly qualified specialists in the field of software, IT-technologies, management of electrical components, the development of the mechanical part. The work of all divisions of the company — production and technical departments, marketing and sales departments — is aimed at market requirements and user wishes. Thanks to a well developed strategy and an attentive approach to current production tasks, iECHO today can offer the best digital solutions in the field of cutting materials. A long period of research and practice has enabled iECHO to create a group of professional experts who, thanks to their knowledge and experience, are able to effectively influence decisions made aimed at improving product quality and production efficiency . All this enables iECHO to maintain a strong position in fierce competition.

Improving product quality is the main way enterprises compete in the modern world. Company iECHO certified ISO9001 quality system certification, and compliance with EU standards of equipment (CE). The production and assembly of iECHO equipment is carried out in Hangzhou. The company imports the main components; all mechanical components and parts are of its own production. IECHO factory has high-precision CNC machining complexes, precision CNC milling machines, high-speed lathes, drilling and grinding equipment that ensure accuracy and stable reproduction of parts. For the most effective quality control of products, all products are manufactured on a modular basis.

IECHO products have successfully entered the markets of East Asia, Europe, Africa and America and other regions of the world. In China, there are four marketing centers and service support services in the eastern, central and southern provinces, as well as in northern China.

Test questions:

1. What cutting methods are used in the clothing industry?

2. What types of cutting systems are Bullmer currently used in?

3. What year Hangzhoui ECHOScience Technology Co. , was founded . Ltd. ?

4. What is PREMIUMCUT ULS ?

5. Describe the technical specifications of the iECHO GLK plotter.

1.2. Innovations in the technological process and their application in practice

1.2.1. Methods of connecting parts of the product.

Clothing is a complex structure, assembled from several pre-prepared and individual parts. The basis for the assembly of clothes are compounds made in various ways. Their choice depends on the requirements for assembly operations and on the properties of the material used for clothing.

Currently, various methods of connecting parts of the product are used: thread, glue, welded, rivet, injection and combined . New methods are also being developed and existing methods are being modified.

Thread seams in the manufacture of clothing are used for joining and processing the edges of parts, as well as for finishing products. In appearance and design, filament seams are diverse. Their design is determined by the location of parts and lines in the seam and the size of the allowance. Depending on the design and purpose, filament seams are divided into connecting, edge and finishing.

The quality of the appearance of the thread stitches is determined by the correct arrangement of the knots of the weave of the threads in the stitches, observing the specified size of the stitches, the snug fit of the threads in the stitches to the material.

The use of adhesive materials is one of the significant reserves for improving the quality of garments, as they allow you to create and maintain stable forms of parts and assemblies of various clothes.

Bonding of clothing parts in comparison with a universal thread connection has a narrower area of distribution and is used in the manufacture of clothing from a limited range of materials.

A significant range of materials is unsuitable for bonding due to a possible deterioration in their appearance or due to insufficient reliability and strength of the obtained adhesive joints.

Also, adhesive seams are unstable to boiling in water and an alkaline soda solution and therefore they are recommended for the manufacture of clothes that are not subjected to washing.

Along with the currently prevailing method of thread joining clothing parts, a new joining method, welding, is of great importance . The use of welding in the apparel industry provides an increase in labor productivity, partial or complete exclusion of sewing threads from the technological process, provides an improvement in the quality of garments, creates conditions for the automation of technological processes for assembling parts and assemblies of garments.

Welded joints of two or more parts are performed on thermoplastic synthetic materials under the influence of heat and pressure, as a result of which a melt of these materials is obtained, which, after heat removal and pressure reduction, hardens and forms an integral connection.

The strength of welded joints is 30-60% of the strength of filament seams.

However, the welded method uses only for synthetic fabrics.

The combined method is a combination of two connection methods: thread and glue, thread and weld or glue and weld.

The combined method is considered complex and time-consuming, therefore, it finds very limited application. This method is used where other connection methods cannot provide adequate protection (for example, in the manufacture of protective and special clothing).

In the clothing industry, a number of metal and plastic parts (buttons, buttons, eyelets, hooks, loops, etc.) are fixed to the corresponding parts of the clothing with riveted joints . When fastening these parts, rods (riveting elements) are inserted into the corresponding hole in the fabric structure, and then they are riveted. The disadvantages of this method include through holes and the inability in this regard to disassemble the fastened garment unit.

Injection molding is one of the main polymer processing methods.

1.2.2. Bonding and welding of clothing parts.

The world's leading manufacturers are actively using welded joints in the manufacture of products from various materials.

Replacing filament welds with welded has a number of advantages :

- the absence of punctures - there is no violation of the waterproofness of the material and the absence of migration of insulation through the seam;

- higher productivity due to the combination of several operations;

- thermal and / or glue treatment of the edge, which is important for loose and knitted fabrics;

- cost reduction - no threads, needles, spools, etc .;

- a modern, attractive, competitive appearance of the product;

Widespread use of the following non-threading technologies:

· Hot glue welding (TKS);

· Ultrasonic welding (USS);

· High frequency welding (HDTV);

· Hot air welding;

· Welding with a hot wedge.

The last three technologies are mainly used for welding PVC fabrics in the manufacture of waterproof work clothes, inflatable boats, summer gazebos, inflatable structures.

Its essence is in gluing two materials together using hot-melt adhesive and Hot-film films . The technology is simple, it can be mastered by any sewing industry from a sewing workshop to large enterprises.

To manufacture products from thin elastic knitwear for sportswear, underwe ar and thermal underwear , a modern type of equipment is used - hot - melt machines that resemble an overlock with a program control unit. Machines produce welding at low temperatures, at which the knitwear is not deformed. The seam is flat without loss of elasticity in all directions, which is impossible to achieve with a thread seam. Some machines are used for lap welding, while others are used for hemming and edging. As a consumable - a special elastic hot-melt adhesive tape is used.

But the most popular at the moment in the world of threadless technologies is hot-melt welding of cut elements and decorative trim on thermal presses. They are in almost every production, they are very versatile and significantly expand the possibilities of production. Moreover, their cost is not very high. Thermal presses are simple and unpretentious in operation, do not require global study and training. The only thing necessary is that the press be either with a moving table or an increased lifting height of the working heating plate, sufficient for comfortable and safe operation. And also for this technology “book” manual thermal presses are not suitable, because when using them, significant displacements of the workpieces among themselves are possible in the process of lowering the working plate. Welding and decorative finishing of welded (set-in) and patch pockets, welding of lightnings, application of shoulder, elbow and other reinforcements, welding (bonding) between different fabrics and materials, welding of labels, logos and reflective elements are performed on thermal presses using Film hot-melt films . , increasing the stiffness of the windbreaks of the zippers and visors of the hoods.

Bonding technology is a seamless connection of pieces of fabric under the influence of heat treatment. A similar bonding technology is offered by Framisitalia. Gluing takes place on industrial equipment using special tapes. At the moment, this technology is difficult to apply for mass production because of the high cost, but it has prospects and a huge market in the future.

One of the first designers to use this technology was Issei Miyake, famous for his innovations. The designer showed the SS17 ready-to-wear collection, in which he didn’t just replace sewing technology with gluing, the idea was to combine fabrics of different densities - soft flowing knit fabric and stiff fabric that creates a stiff but flexible texture. The effect was comparable to a spring falling on the stairs - the elements of the dress spring on the models to the rhythm of music and movements.

Figure 1.2.1.

Almost all the world's leading manufacturers, to one degree or another, apply hot-melt adhesive technologies in their products: the production of various kinds of clothes (from underwear to down jackets, from casual, sportswear to special clothes), shoes, equipment and accessories.

Why glue it? A filament seam has a number of significant drawbacks and limitations in the modern production of fashionable and functional clothing, which at the same time tends to a minimum cost. First of all, needle punctures violate the integrity and tightness of the material, which is important for manufacturers of top waterproof and windproof clothing, tents, equipment and other products. Secondly, sewing on elements of complex shapes often requires sophisticated equipment and highly qualified seamstresses. Thirdly, the price of the operator’s error is high: if he “leads away” the seam, the product will be damaged. Fourth, thread seams are not elastic in several directions. And on bulk fabrics, they require shear processing, which increases the thickness of the seam, all of which is fundamentally important for modern elastic and knitted fabrics, where they tend to flat elastic seams. And fifthly, it is not always possible to sew any element on the finished product, for example, an identifier for special clothes or a uniform (chevron with a logo or name), external reinforcement, add pockets to the insulated jacket, this can only be done by stitching through and through the entire product, which will lead to the loss of its water resistance and thermal insulation properties, not to mention the aesthetic component of the product.

Hot glue technologies are devoid of all these disadvantages, since the films are glued with their entire surface area in one operation, without violating the integrity of the material and are additionally sealed and reinforced from abrasive effects.

What exactly is the essence of this non-filament hot-melt welding, and the essence is extremely simple and understandable and consists in gluing two materials together (bonding), the principle of joining, as we all know, double-sided adhesive tape.

To connect the details of the cut, accessories, hot-melt welding of accessories and accessories (zippers, stoppers, labels, hangers, transparent windows), patch and set-in pockets, bonding the collar area with soft and tactilefriendly materials, film adhesive films are used .

Fig. 1.2.2.

Using these materials, it is possible to produce a hot-glue stitch of down products, thereby departing from the additional package and completely eliminating the migration of down through the seams. This stitch is now widely used for light down jackets, down sweaters, down liners and down sleeping bags.

Figure 1.2.3.

There are also adhesive films with an internal court to increase the rigidity of the material to be glued, such films are used to form hoods, windbreaks for zippers, cuffs, pocket flaps, etc.

The second type of decorative film . They carry not only a decorative and design function, but also functionality, for example, external sealing, reinforcement, to create retroreflective elements or in the form of reinforcing antislip pads.

Fig. 1.2.4.

The third - hot-melt films for special purposes . Most of these hot-melt adhesives go on a textile or knitted basis and are designed to externally strengthen problem areas (shoulders, elbows, knees, etc.). Or for internal reinforcements, sealing joints of seams, zippers, embroideries, joining internal parts with accessories, a hanger, and a clamp for tightening sewn on them.

Fig. 1.2.5.

Ultrasonic welding

Initially, this technology was used for a narrow circle of non-woven materials in the production of filters, disposable clothing, packaging and home textiles. It was practically not used in the manufacture of products from woven materials due to the insufficient strength of the seam and the piercing sound that the machine makes during operation. But technology does not stand still, and these shortcomings were eliminated, silent machines appeared that weld a wide range of different materials, almost all synthetic, mixed, knitted fabrics.

Ultrasonic welding does not require consumables (threads, needles, spools, sealing tapes). On ultrasonic machines, it is possible to simultaneously trim the edges, cut, decoratively cut the pattern, heat-treat the cut edge, emboss, including the logo (including on the skin) at the same time as connecting the parts. In addition, butt welds can be made on such equipment, resulting in a flat seam. This allows you to work with a fairly complex geometry cut. But this seam is not strong enough due to the small area of the connection and it must be additionally glued with a special tape on a textile basis. Ultrasonic machines for the most part are made in the housing of standard industrial-class sewing machines, which greatly simplifies and reduces the time for retraining seamstresses, and the transition to new non-threading technologies.

All these advantages of modern equipment greatly expand production capabilities, increase its productivity, reduce the cost of products, increase profitability and competitiveness, which is strategically important in our difficult time for Russian production.

Welding is a technological process of the formation of an integral connection by bringing the joined surfaces in the tissue contact zone to a viscous state with subsequent fixation. Welding is a process of self-adhesion of thermoplastic materials under the influence of heat and pressure. The use of thread compounds for such materials is irrational, since the sewing process is difficult, products with thread seams do not have sufficient strength and water resistance. Glue joints are also unsuitable here, since the material itself is thermoplastic, and therefore hot pressing is not possible. In the manufacture of products from thermoplastic film materials (plasticized polyvinyl chloride, polyethylene, polyamide), welded joints are used. Three types of welding are used in sewing production: thermal contact (continuous and thermal pulse), highfrequency and ultrasonic. To date, the most practical applications in the clothing industry have been thermocontact welding using electric heating by the method of sequential processing of semi-finished products and thermal pulses by the method of parallel processing. The essence of the thermal contact welding method is that the material isheated by a special tool and in direct contact with the material. Heater Temperature 300-350 on S. To avoid sticking of use gaskets made of teflon, tracing paper. The heating of the tool can be gas, induction, electric.

Fig. 1.2.6.

a, b - plastic packaging; c - application; g, d, e - quilting fabric with insulation

In sewing production, the sequential welding method is mainly used. Sequential welding with electric heating is carried out using heating elements in the form of a wedge-shaped soldering iron, roller, tape. For welding thermoplastic films with a thickness of 0.25–1 mm, as well as textile materials with a thermoplastic polymer coating, it is advisable to use a wedge-shaped soldering iron, which, as a result of heating the internal surfaces of the parts to be welded, provides a weld in the contact zone with its subsequent fixation by pressure rollers . In this case, the processing methods are parallel-sequential, the material advancement speed is 150 cm / min. In thermocontact welding, heating of the film material is carried out almost instantly due to the transmission of a large current pulse through the heating elements. In the pauses between pulses, the weld is cooled under pressure. The cooled surfaces of the weld do not stick to the heating tool, therefore, thermo-pulse welding can be done without release linings. The simplicity and cost-effectiveness of the thermal contact method allow it to be used for welding thin films and textile materials with a thermoplastic film coating in the manufacture of special and some other types of clothing. Significant disadvantages of the method are: the possibility of overheating of the surface layer of the material, direct contact of the heater with the material and its pressure on the material, which leads to extrusion of the molten material in the heat-affected zone and a decrease in the strength of the joints. In high-frequency welding, materials are placed between the electrodes, to which an alternating current of high frequency is supplied. Heat generated by the electrodes for 2–3 s welds materials. The electrodes remain cold, so there is no need to isolate them. Apparatuses for high-frequency welding are equipped with a set of electrodes of various shapes, therefore, there are two methods of high-frequency welding: parallel and serial. Of greatest interest to the clothing industry as the most productive one is parallel, usually performed on presses. The disadvantage of highfrequency welding is the complexity and high cost of the plants, as well as the need for local or general screening. This welding method is used to make loops, embossed seams in faux leather clothing, collars, cuffs, pockets of men's shirts made of synthetic fabrics, for attaching emblems and appliqués to details of clothing.

Ultrasonic welding is carried out due to the influence of ultrasonic vibrations and pressure. Ultrasonic welding is used to join textile materials from thermoplastic fibers. This heat softens the material, and when pressed, the heated surfaces join in the contact zone. There is no consensus on the mechanism of ultrasonic welding of thermoplastic polymers, including textile synthetic materials. The ultrasonic welding process is considered as the pure action of mechanical vibrations, as a result of which the heat necessary for welding arises from the friction of the surface layers in molecular chains. When welding plastics that do not conduct ultrasonic vibrations well, the energy of ultrasonic vibrations is converted into heat as a result of microshocks or as a result of absorption of ultrasonic vibrations at the welded boundaries. At the initial moment of welding, directly under the waveguide, due to the fact that the highest temperatures arise here, a viscous-flowing layer is formed. Under the influence of welding pressure, it is pressed into the inner layers of the material. With a low surface density of the material, the viscous mass penetrates to its opposite side, providing a warming effect over the entire thickness. Which significantly reduces the duration of welding.

Ultrasonic welding has a number of features:

- heat is generated only in the weld zone, which contributes to a high welding speed and minor changes in the properties of the material;

- it is possible to weld contaminated surfaces, since all foreign particles are removed from the weld zone due to shear vibrations;

- energy can be supplied at a considerable distance from the place of welding, which allows you to weld parts in hard to reach places;

- you can weld various thermoplastics;

- there is a possibility of mechanization and automation of welding processes; –Production processes are characterized by efficiency and purity. Ultrasonic welding is carried out in a sequential way on machines of the continuous type and along the entire contour of the seam in a parallel way on the press equipment. The scope of ultrasonic welding is wider in comparison with high-frequency and thermal contact welding. This method is applicable for joining textile materials from all types of thermoplastic fibers. Ultrasonic welding is used to connect parts of clothing made of fabrics and knitted fabrics, basic lining materials and insulation. By welding, you can get stitch, seam, finish and other seams, make loops, fasteners, attach buttons, etc., perform stitches of different configurations and sizes, performed in sequential and parallel ways. Of greatest interest is the use of the ultrasonic method for threadless buttons fastening to clothing made of fabrics (the so-called “combi-tex” method). Special buttons on the legs of thermoplastic material are mounted on the fabric and pressed on top with a metal plate, and below - with a metal emitter of ultrasonic vibrations. With simultaneous exposure to the button of ultrasonic vibrations and pressure, the material of its leg is heated to a viscous flow state and penetrates the tissue structure, and then is formed on its other side. Using this method on the assortment of shirts allows you to combine the operations of attaching buttons to the front of the shirt and fastening the shirt, since the buttons can be installed through the loops. It is also possible to simultaneously attach buttons to the front, collar and cuffs. Buttons are attached on a specially developed “Combi-tex” installation. Using it, you can attach buttons to individual parts as well as to the finished product. When welding, the need for bonding materials (threads, glue and solvents) required for thread and glue joints is eliminated.

Thus, welding in the sewing industry opens up enormous opportunities for mechanization and automation. In welds, it is not allowed to pull, stretch, fit the material, burn through, unconnected places, punching, distortions, displacements, pollution. The ends of the welded joints are not additionally fixed. Based on this, it can be concluded that welded joints of garments are the most labor-saving and high-performance technology in the garment industry. Using this technology, one can achieve great results in the development of production of cost-effective, aesthetic, competitive and affordable products for the population.

1.2.3. Modern equipment for threadless processing of clothing parts by gluing.

Bonding is one of the common methods for threadless joining of clothing parts with various cushioning materials.

Adhesive technology operations are carried out using the following types of special equipment: irons, batch presses of general and special purpose, specialized continuous presses.

Steam-air mannequins are used for the parallel execution of two operations - wet-heat treatment and gluing.

The main manufacturers of equipment for the gluing of clothing parts in Europe are German companies. Italy also supplies its equipment, although in much smaller quantities.

Table 4 shows information on the assortment of products of the main equipment manufacturers in Germany, Italy and Russia.

Table

4

|

Name of manufacturer |

Types of equipment |

|

The company "Kannegisser" (Germany). Year of foundation - 1948 |

Continuous presses for bonding collar and cuff details for men's shirts. Continuous pneumatic presses of the Multi Star type for duplication of details of clothes. |

|

Firm "Herbert Mayer GmbH" (Germany) |

Presses of periodic and continuous action (floor, table) for duplication of parts of different types of clothing. Robots for feeding and stacking glued parts. Duplicate presses for fur, shoes and leather. |

|

Firm "Fight" (Germany) Year of foundation - 1961. |

Ironing jobs. Steam generators. |

|

4. The company "Legmash" N.Novgorod |

Ironing jobs. Steam generators. Hydraulic batch presses. Press duplicating continuous action PD. |

|

Leased enterprise plant "Agat" Rostov-on-Don |

Industrial irons. |

|

6. Firm "MacPie" (Italy) |

Presses of periodic action. Continuous presses |

|

7. Firm "Malawasi" (Italy) |

Ironing jobs. Steam irons. |

|

8. The company "Schrobel" (Germany) |

Ironing jobs. Steam irons. |

1.2.4. Modern equipment for threadless processing of clothing parts by

welding.

The connection of clothing parts by welding is based on the use of the thermoplastic properties of synthetic materials, which are heated to a viscous state by the energy of high-frequency currents and ultrasound and form a strong joint after a certain pressure after cooling.

Ultrasonic welding.

Ultrasonic beadless machine BShM-1 CJSC Zavod Promshveimash (Podolsk), UZB-600 and UVD-1 Czechoslovakia, roller machine IM-300 firm Branzon Sonic Power (USA), roller machine IM-22 firm Omega (Great Britain), installation portable welding GK-4 firm "Branzon Sonic Power" (USA).

High frequency electric welding.

Installation “Fallipress-800” of the national enterprise “German Schlimme” Germany, installations UZP-2-2,5E and UZP-2500A of the factory “Industrial Electronics” Bulgaria.

Thermal contact welding.

The UTS GZ installation of OJSC “Orsha” designed for temporary spot welding before gluing parts.

PFAFF 8303 Classic machine for sealing joints with thermoplastic tapes using hot

air

Figure 1.2.7.

Name: PFAFF 8303 Classical machine for sealing joints with thermoplastic tapes using hot air Type: Welding machines Productivity:

• Patented two-chamber nozzle, uniform welding temperature and optimal welding along the edges of the tape

• Microprocessor control with error diagnosis.

• Automatic cutting of the tape (saving tape)

• Time-adjustable nozzle rotation (excluding burning of the membrane at the end of the seam)

• For a better view, the machine head is tilted 18 degrees from the operator.

• Various columns for clothes and shoes

• Rollers and nozzles of various widths for tapes 22 and 25 mm wide.

•Max. welding temperature 650 gr.

• Welding speed up to 10 m / min.

• Power of a heating element is 3 kW.

• Mains voltage 230 V., 1 phase.

• Working pressure of compressed air is 6 bars. Air consumption is up to 120 l / min.

PFAFF 8303-040

• Column tilt from the operator

• For clothes

• Belt width 22 mm.

• Width of rollers is 25 mm.

PFAFF 8303-041

• Tilt column from the operator

• For clothing

• Band width 25 mm.

• Width of rollers 28 mm.

PFAFF 8303-042

• Column tilt per operator

• For shoes

• Belt width 22 mm.

• Width of rollers is 25 mm.

PFAFF 8310 Ultrasonic Synthetic Fabric Welding Machine

Figure 1.2.8.

Name: PFAFF 8310 Ultrasonic welding machine for synthetic fabrics Type: Welding machines Productivity Sewing speed: 10 m / min.

Programmed welding with PFAFF 8310. Seamsonic type ultrasonic welding machine combines all the physical advantages of ultrasonic welding with the experience of sewing technology in a way that is still unique. On the PFAFF 8310, the welding material is fixed between the impulse and pressure wheel and is subsequently welded under pressure. With this method of ultrasonic welding, the welding material is “whipped” by means of sharply changing pressure fluctuations. Due to molecular vibrations, heat is generated in the lower surface of the welding material, on thin materials it is in the immediate vicinity of the weld joint, which ensures a good connection of materials. Applications PFAFF 8310

Technical field: Filter pockets, personal care products, medical mattresses and covers, felt, surgical dressings, film, body armor, sun protection, filters, insulation, shower curtains, etc.

Manufacture of wearing apparel:

Leisure clothing, protective clothing, bodice, underwear, operating clothing, etc. Automotive industry : Awnings for trucks, curtains, awnings and much more.

Accessories:

■ Digital SPS control

■ Maintenance using the Touchscreen control panel

■ Functions: manual and automatic operation with stepless speed adjustment using the foot pedal, amplitude adjustment from 50 to 100%, delayed start for oscillations and drive, idle and reverse adjustment.

■ The machine is delivered optionally with a free sleeve, a reverse sleeve platform for lap seams and tubular products, a core sleeve (sleeves can be interchanged), and also with a flat platform.

Ultrasonic Generator:

■ new: power stabilizer

■ silent 35 kHz

■ automatic tracking of amplitude depending on frequency and speed

■ automatic adjustment of the impulse wheel before welding and during welding Accessories (options):

■ Possibility of milling or engraving of clamping wheels according to the customer’s model, overlap guides, seams and hemmers

■ puller left and right and with separate disconnection.

New: Cut & Seal PFAFF 8310 Cut & Seal combines physical cutting processes with ultrasonic welding. Based on the 8310-003 machine that has been successfully used on the market, new generation ultrasonic welding machines have been developed. Advantages:

■ Two operations in one run (Cut & Seal)

■ Minimum seam allowances (microsheaths) for high strength ■ High comfort of welded materials

■ Flat seams after subsequent processing The latest trend in joining textile seams. Ultrasonic welding machine for simultaneous welding and edge trimming. Sequential processing of flexible thermoplastic and non-woven

materials.

Figure 1.2.9.

Name: PFAFF 8320 Direct welding with hot wedge or hot air Type: Welding machines Productivity

Differences between hot wedge welding and hot air welding.

Hot wedge welding:

-The welding seam is always neat.

- The energy consumption is up to 80% less than when welding with hot air. -Air consumption is significantly lower than when welding with a hot wedge. A small compressor is enough.

- When welding with hot wedge, 95% less harmful vapors are formed than when welding with hot air.

-Due to direct contact, the hot wedge should be resurfaced regularly. In this regard, there are additional costs for restoring the wedge. Hot air welding: - The welding seam is slightly wavy, the edge is partially noticeable.

-The energy consumption is 5-6 times higher than when welding with a hot wedge.

-Significant air consumption. A large compressor is needed.

- When welding with hot air, 20 times more harmful vapors are formed than when welding with hot wedges.

-When welding non-woven materials, such as filter materials, the seam is more elastic due to the penetration of hot air into the material.

- Due to the lack of direct contact, there is no need to polish the wedge. There are no additional costs.

PFAFF 8320 Stationary machine for welding flexible thermoplastic materials using HOT WEDGE or HOT AIR.

• Completely freely programmable machine

• All parameters are entered using the interactive control panel

• Drive of transporting rollers from individual stepper motors with the possibility of differential material supply

• High column with variable geometry. Possibility of turning 180 g.

• Height-adjustable bed

• Fast transition from hot-wedge welding to hot-air welding for various applications • Length 1100 mm.

• Width 620 mm.

• Height 1400 mm.

• Departure of a sleeve of 480 mm.

• Weight 140 kg.

• The passage between the rollers is 25 mm.

• Welding speed up to 10 m / min. Optional up to 30 m / min.

PFAFF 8320-010 Hot Wedge

• Max. welding temperature 500 gr.

•Max. seam width 30 mm. (depends on the width of the wedge). Standard wedge options: 7, 9, 12, 15, 20, 30 mm. • Mains voltage 230 V., 1 phase.

•Max. power consumption 1.5 kW.

• Operating pressure of compressed air 6 bar.

• Air consumption up to 30 l / min.

PFAFF 8320-020 Hot air

• Max. welding temperature 650 gr.

•Max. seam width 30 mm. (depends on nozzle width). Standard nozzle options: 15, 20, 30 mm.

• Mains voltage 230 V., 1 phase.

•Max. power consumption 3,5 kW.

• Operating pressure of compressed air 6 bar.

• Air consumption up to 150 l / min.

PFAFF 8320-020-061 Hot air Special equipment for welding continuous filter bags

• Equipped with a nozzle 15 mm wide as standard.

• Equipped with 30 mm wide casters as standard.

• It is standardly equipped with an overlapping seam apparatus with adjustable seam widths from 10 to 30 mm.

• Standardly equipped with a hose former with diameter adjustment from 60 to 300 mm.

Figure 1.2.10.

Name: PFAFF 8330 Fully programmable machine for sealing seams with thermoplastic tapes using hot air Type: Welding machines Productivity

Fully freely programmable machine

• All parameters are entered using the interactive control panel

• Drive of transporting rollers from individual stepper motors with the possibility of differential material feed

• Dynamic welding (change in the power of the heating element depending on the welding speed) • Automatic cutting of the tape at the end of the material according to the signal from photosensor

• Quick-change speaker system for various applications

• Rollers and nozzles of different widths for tapes 22, 25 and 30 mm wide.

•Max. welding temperature 650 gr.

• Welding speed up to 10 m / min. Optionally up to 20 m / min.

• The power of the heating element is 3.3 kW.

• Mains voltage 230 V., 1 phase.

• Operating pressure of compressed air 6 bar

• Air consumption up to 150 l / min.

WELDING MACHINE: ELMRT

Figure 1.2.11.

Name: ELMRT Type: Welding machines Productivity Standard ultrasonic machine 40 kHz 1500 W Titanium rotating sonotrode Wheel with standard knurling (15 types to choose from) Integrated PLC controller controlling speed / delay and frequency

Figure 1.2.12.

Name: SC40 Type: Welding machines Productivity: Standard ultrasonic machine 40 kHz 600 W Hardened steel sonotrode Wheel with standard knurling

(15 types to choose) Integrated PLC controller controlling speed / delay and

frequency Stainless steel worktable 500 x 500 mm

WELDING MACHINE: SC20

Figure 1.2.13.

Name: SC20 Type: Welding machines Performance: Standard ultrasonic machine 40 kHz 1500 W Hardened steel sonotrode Standard knurled wheel (15 types to choose from) Integrated PLC controller controlling speed / delay and frequency Stainless steel worktable 500 x 500 mm

Test questions:

1. What is a non-filamentous tissue connection?

2. What methods are used for non-thread compound tissue?

3. Bonding technology - is it?

4. Can materials be joined by welding?

5. Types of machines used for threadless connection of parts?

1.3. Innovations in the work of molding and finishing products, the choice of

Intermediate and final ironing are obligatory operations in the clothing industry, which are, first of all, essential for recognition of the product by the end user. Equipment for wet-heat processing of garments is one of the main types of machines and apparatuses used in the manufacture of clothing. It includes universal press equipment, special press equipment, ironing tables, irons, auxiliary equipment and others (steam generators, vacuum plants, etc.).

Most installations, presses and ironing tables are a complex consisting of presses of basic structures, tables and component pillows, irons.

The basic designs of presses and duplicating plants differ in a number of basic ways. These signs include the pressing force, the type of drive, the degree of automation (type of control), the degree of energy supply.