Development of a New Design for Drying

Cotton Seeds with Purpose of Efficient Use of

Heat

Sayitqulov Sardor Oltiboyevich, Fayziyev Sirojiddin Hayot o’g’li, Mardonova Ferangiz Bahron qizi, Raxmonov Xayridin Qodirovich.

PhD student of the Department "Light industry machinery and equipment" of the Bukhara Engineering-Technological Institute, Uzbekistan.

PhD student of the Department "Light industry machinery and equipment" of the Bukhara Engineering-Technological Institute, Uzbekistan.

Master’s degree of the Department "Light industry machinery and equipment" of the Bukhara EngineeringTechnological Institute, Uzbekistan.

Doctor of Technical Sciences, Professor of the Department "Light industry machinery and equipment" of the Bukhara Engineering-Technological Institute, Uzbekistan.

ABSTRACT: The article analyzes the current research in the field of drying cotton, focusing on the light industry and measures to introduce modern forms of cotton and textile production. The analysis of heat consumption in cotton drum drums was carried out on the basis of which a pilot test was conducted to determine the amount of heat loss in the drum. In addition, a new design of the screw conveyor used for drying and transporting cotton seeds using the secondary heat flow used to heat the air consumed for the drying drum and the drying drum.

KEY WORDS: Tumble dryer, cotton, hopper, feeder, screw, fiber, seeds, temperature, moist air, hot air, pipe, fuel.

Today, the industry in our country is moving to a new level of quality assurance. Traditional and spiritually outdated technologies are being replaced with the use of high-tech, high-quality products and new technologies that enhance standards for handling them.

The increasing demand for natural cotton wool in the global market has set many production companies under certain responsibilities. According to the International Consulting Committee (ICAC), "China, USA, India, Pakistan, Brazil, and Uzbekistan are leading the way in supplying cotton to foreign markets" .2016-2017 (22.48 million tons), the demand for timber is 1.7% (24.09 million tons). Cotton processing is practiced mainly using the technologies of the US, China and Uzbekistan.

According to the Resolution of the Cabinet of Ministers of the Republic of Uzbekistan dated January 25, 2018 "On measures for introduction of modern forms of organization of the cotton-textile industry", currently there are 13 "Cluster" Limited Liability Companies established in 13 regions of the country. This indicates an increased focus on the industry and the fact that the ginneries face a great deal of responsibility. In particular, it is important to create techniques and technologies to ensure the preservation of the quantity and quality of raw cotton produced by the ginneries, to reduce the consumption of raw materials and energy.

According to the Resolution of the Cabinet of Ministers of the Republic of Uzbekistan dated January 25, 2018

"On measures for introduction of modern forms of organization of the cotton-textile industry", currently there are 13 "Cluster" Limited Liability Companies established in 13 regions of the country. This indicates an increased focus on the industry and the fact that the ginneries face a great deal of responsibility. In particular, it is important to create techniques and technologies to ensure the preservation of the quantity and quality of raw cotton produced by the ginneries, to reduce the consumption of raw materials and energy.

In the world practice, the development of new techniques and technologies for pre-processing of raw cotton, which have a positive impact on the technological processes of initial processing of cotton, the quality of the products, is of special importance. In this regard, the most important task is to use the heat flow efficiently during the drying process, to establish scientific basis for the use of secondary heat energy released into the atmosphere, and to develop new technologies and techniques for cotton drying using secondary heat flow.

II. THE SIGNIFICANCE OF THE SYSTEM.

Nowadays, patents for an average of four hundred thousand inventions worldwide are issued annually. This means that every half-minute one new invention occurs. At the same time, countries where inventive invention places the greatest emphasis on technical creativity, are developing rapidly.

Particular attention is paid to the sustainable development of primary cotton processing enterprises, the development of technical facilities and technologies at the sector enterprises, the increase in the level of efficient use of production capacities, and the production of high quality competitive products on the world cotton market. In this regard, particular attention is given to the improvement of high-performance cotton reprocessing machines and the creation of resourcesaving technologies at the world cotton processing enterprises. Wide-ranging research is being carried out around the world to improve the techniques and technology of primary cotton processing, theoretical research and the establishment of the scientific basis for the links between the speed of movement of working parts, the energy consumed and the productivity of machines. In particular, it is important to create techniques and technologies to ensure the quantity and quality of raw cotton produced by ginneries, to ensure the quantity and quality of produced cotton products, to reduce raw materials and energy consumption. A number of measures are being taken in the Republic to improve the technical and technological re-equipment of cotton industry enterprises, increase the profitability of cotton raw materials processing, and increase the competitiveness of the products.

A number of priority areas are being studied throughout the world, including the creation and improvement of cotton cleaning equipment and technologies, including the development of effective cotton cleaning techniques and technologies, the determination of the degree of impact of the heat on the moisture content of the cotton, the multicomponent material. Taking into account the fact, the drying parameters and the fiber quality preservation are being developed.

The moisture content of cotton must be no more than 8-9 % for the purpose of obtaining a quality fiber during cleaning and separation. For this reason, cotton is dried in 2SB-10 drum dryers.

Experience of working 2SB-10 drying drums at cotton gin has shown that they have some drawbacks.

One of the most important fuel, heat and air

consumption is very high, the drum 15000 ![]() / hour to 24000

/ hour to 24000![]() / hour

of hot air at 80

/ hour

of hot air at 80 ![]() to 250

to 250 ![]() temperature.

temperature.![]()

For drying cotton, it is necessary to heat the water and its contents to the evaporation temperature so that the heat evaporates. Cotton, heating the water contained in it, and the heat used to evaporate moisture are useful. Determine their share in relation to total heat.

Grapho-analytical calculation of heat accounting of high-yield cotton seeds drying and cleaning equipment In grapho-analytical calculation of heat spent on drying and cleaning equipment, we perform thermal calculations on existing and proposed variants:

We will analyze the heat consumption of the existing drying equipment as follows. The amount of heat supplied to the dryer will be:

- Evaporation of cotton moisture (

-

![]() To go out with the air used ( ;

To go out with the air used ( ;

- Cotton falling on a drying drum (Q3 q3);

- Heat the inside of the drums from the exhaust pipe (

-

![]() All of

which is spent on the environment surrounding the drum ( ;

All of

which is spent on the environment surrounding the drum ( ;

Considering the above, we consider the improved drying drum to be heat-analytically based on the baseline data given below.

![]() Productivity

of wet cotton,

Productivity

of wet cotton, ![]() = 12000 kt / h; Initial moisture content

of cotton seeds

= 12000 kt / h; Initial moisture content

of cotton seeds ![]() = 12%; Moisture of dried cotton seeds. W2

= 8.0%; Outdoor temperatures.

= 12%; Moisture of dried cotton seeds. W2

= 8.0%; Outdoor temperatures. ![]() = 20 °C; Initial humidity of air supplied

to the drying drum; The heat supplied to the dryer. = 160 °C, = 80 °C; The

moisture content of the air leaving the dryer is d2= 30 gr. kg build

the weather; The temperature of the cotton seeds supplied to the drum.

= 20 °C; Initial humidity of air supplied

to the drying drum; The heat supplied to the dryer. = 160 °C, = 80 °C; The

moisture content of the air leaving the dryer is d2= 30 gr. kg build

the weather; The temperature of the cotton seeds supplied to the drum. ![]() = 20

°C; The temperature of the cotton leaving the drum is 02= 50 °C;

= 20

°C; The temperature of the cotton leaving the drum is 02= 50 °C;

Primary dirt of cotton seeds Z = 12%

- Weight of moisture evaporated from the dryer in 1 hour

![]() (1)

(1)

![]() = 428,6 kg/

hour

= 428,6 kg/

hour

- Dry cotton weight leaving the dryer

![]() (2)

(2)

![]() = 11571,4

gr/kg.hour

= 11571,4

gr/kg.hour

- The dry formula for evaporating 1 kg of moisture is calculated by the following formula.

-

L![]() (3)

(3)

L![]() = 40 gr/kg moisture

extraction

= 40 gr/kg moisture

extraction

Bu yerda; ![]() =5 gr/kg.dry.air

=5 gr/kg.dry.air

- Total dry air consumption.

![]() L=l Wвв=40 428,6=17142,86

kg/hour

L=l Wвв=40 428,6=17142,86

kg/hour

- The volume of wet air.

![]() V=L =17142 9

0,854=14640

V=L =17142 9

0,854=14640![]() /hour

/hour

Ʋ_pn to calculate

![]()

![]() = 20

= 20 ![]() and

=5 g / kg the air in it =0,854 kg of air we find,

mainly, the hot air fan V = 24629,4, which should take into account the

resistance of the hot air pipes.[2]

and

=5 g / kg the air in it =0,854 kg of air we find,

mainly, the hot air fan V = 24629,4, which should take into account the

resistance of the hot air pipes.[2]

- Specific heat spent on evaporation of 1 kg moisture (j / kg)

![]() )

(4)

)

(4)

![]()

![]() j/kg =( )=

(2609080-418720)=2564,7 here - 2491 +1968 =2491000+196860=2648440 j/kg

j/kg =( )=

(2609080-418720)=2564,7 here - 2491 +1968 =2491000+196860=2648440 j/kg

- Heat evaporation rate J / hour

![]() =2564 7 428 6=1099157,1

kj/kg

=2564 7 428 6=1099157,1

kj/kg

- Specific heat consumption (j / kg)

![]()

![]()

![]() =L

(944,83+1,97 ) ( )=40 (944,83-1,97 30) (80-20)=2125,8 kj/kg

=L

(944,83+1,97 ) ( )=40 (944,83-1,97 30) (80-20)=2125,8 kj/kg

Here: (944.83 + 1.97 ) - Outdoor Heat Size (jk / kg grad)

L_speed - outgoing air consumption, kg / hour

- Heat loss for drying agent (J / kg)

![]() kj / hr = =

468.6 2125.8 = 911036.6

kj / hr = =

468.6 2125.8 = 911036.6

- Comparative heat consumption. (J / kg)

= (5)

![]() In this

occasion: =1.6 kJ / kg grad. = 4.19 kj / kg grad In that case.

In this

occasion: =1.6 kJ / kg grad. = 4.19 kj / kg grad In that case.

![]() (50-20)=1451,4 kj/kg

(50-20)=1451,4 kj/kg

![]() =1,792 kj / kg

grad

=1,792 kj / kg

grad

![]() Here: -loaded

heat capacity of cotton, (kJ / kg grad)

Here: -loaded

heat capacity of cotton, (kJ / kg grad)

-

Temperature of cotton seeds entering and leaving drying drum,![]()

- Heat consumption for cotton in drum (J / kg)

-

![]() =428,6

1451,4=622028,6 kj/hour

=428,6

1451,4=622028,6 kj/hour

-

![]() The time

it takes to heat the drying drum. =0, =0;

The time

it takes to heat the drying drum. =0, =0;

- Specific heat consumption, (j / kg)

![]() (6)

(6)

![]() =100,7 kj/kg

=100,7 kj/kg

Heat consumption around the drum, (j / h)

-

![]() =428,6

176.2=43142,4 kj/kg

=428,6

176.2=43142,4 kj/kg

Total heat consumption.

ΣԚ=![]()

ΣԚ=![]() =1099157.1+911036.6+622028.6+0+75499.2=2675365

=1099157.1+911036.6+622028.6+0+75499.2=2675365

16. The sum of specific heat loss is equal to:

![]() Σq=

Σq=

Σq==2564.7+2125.8+1451.4+0+176.2=6242.5

- The usefulness of the drying drum

![]() Ƞ= 100%

(7)

Ƞ= 100%

(7)

Ƞ= 100%=

According to analysis and experiments, 2SB-10

dries about 35% of hot air in the drying drum. Fig-1.![]()

When wet cotton is dried in this dryer, the

temperature of the drying agent within the first four meters of the drum drops

from 280 ° C to 125 ° C, where the cotton is heated and the moisture in the

large (250 m2 / kg) surface is evaporated. In the next drum, the

drying agent's temperature drops to 70-80 ° C, and the surface of the seeds

evaporates. However, the cotton pulls moisture out of the environment very

quickly until it goes through a few tenological processes of drying out the

drum, thus increasing its moisture balance and increasing the moisture balance

when the temperature drops. As you can see, the moisture content of cotton can

be seen in the low quality and quality of fiber and seeds.![]()

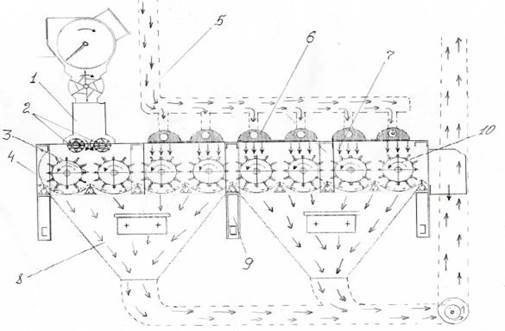

The new device proposed by researchers from the Bukhara Engineering-Technological Institute, which is the alternative energy source, including the hot-air welding and drying unit (Fig-2), maintains the moisture content of the cotton until the next process. At the same time, the cotton cleaning efficiency and the amount of fiber produced during the cleaning process increase significantly.

Fig-1. 1-Cotton bunker , 2-Roller.3,10- Drum with pile ,4-Grid surface, 5-tube, 6-Hot air conductor, 7- Hot air, 8- Garbage bunker, 9-Stake.

This device is mounted on a complex for cleaning raw cotton from small impurities 1XK and works as follows. The seeds fall into the shaft 1 mounted on the feed rollers, the feed rollers 2, rotating in opposite directions, feed the upper cotton seeds to the stack of the drum 3, the pile drum draws the cotton over the surface 4 and pushes it into the second drum. At the same time, the secondary hot air leaving the drying drum 2SB-10 is transferred by the hot air atomizers through the pipe 5 to the air atomizing nozzle 6 of the hot air above the pile drum 3. The flow of hot air 7, beats on the cotton above each drum passes into the mesh surface 4, and through the suction pipe 11 leaves the machine. The advantage of this method is that the reuse of 35% of the hot air that enters the atmosphere from the calf drum can significantly improve the process of cleaning cotton from small impurities.

In conclusion, using a 35% secondary air flow from the 2SB-10 drying drum can significantly increase the amount of fibers obtained by the second drying of the cotton seeds, along with the efficiency of cleaning cotton seeds. In addition, it is possible to preserve the fiber, fluff and dust particles contained in cotton into the hot air.

1. Sayitqulov S.O.,Mardonova F. “Innovative solutions of engineering and technological problems of modern production” 14-16 November.

“Basics of designing a cotton drum drying drum” 597 page. Bukhara 2019 y.

2. S.D.Boltaboyeva, A.P. Parpiyev: “drying of cotton seeds” Toshkent, Teacher 1980 year 146 page.

3. Boltaev B. “Improvement of drying equipment to preserve the natural properties of cotton” dissertation. 49-page, 2014 year

4. Raxmonov X.Q. “Initial processing of light industry raw materials” training Guide Toshkent : Editorial Publishing, 312 page, 2018 y

5. Raxmonov X.Q. Fayziyev S.H. “Improvement of equipment and technology of drying of the cotton mass and its technological assessment on the basis of its thermal properties” International journal of advanced research in science, engineering and technology. page:9496-9500, Vol.6, Issue 5, May 2019.

Sayitqulov Sardor Oltiboyevich -PhD student of the Department "light industry machinery and equipment" of the Bukhara Engineering-Technological Institute, Bukhara city, Uzbekistan.

Fayziyev Sirojiddin Hayot

o’g’li -PhD student of the Department "light industry machinery and

equipment" of the Bukhara Engineering-Technological Institute, Bukhara

city, Uzbekistan. machinery and equipment" of the Bukhara

Engineering-Technological Institute, Uzbekistan. Bukhara city, Uzbekistan.

Fayziyev Sirojiddin Hayot

o’g’li -PhD student of the Department "light industry machinery and

equipment" of the Bukhara Engineering-Technological Institute, Bukhara

city, Uzbekistan. machinery and equipment" of the Bukhara

Engineering-Technological Institute, Uzbekistan. Bukhara city, Uzbekistan.

Raxmonov Xayridin Qodirovich -Doctor of Technical Sciences, Professor of the

Department "light industry machinery and equipment" of the Bukhara EngineeringTechnological Institute, Bukhara city, Uzbekistan.

Материалы на данной страницы взяты из открытых источников либо размещены пользователем в соответствии с договором-офертой сайта. Вы можете сообщить о нарушении.