Smart Manufacturing

Smart Manufacturing

Editors

Zhuming Bi

Li Da Xu

Puren Ouyang

MDPI • Basel • Beijing • Wuhan • Barcelona • Belgrade • Manchester • Tokyo • Cluj • Tianjin

Editors

|

Zhuming Bi Purdue University Fort Wayne USA |

Li Da Xu Old Dominion University USA |

Puren Ouyang Ryerson University Canada |

Editorial Office

MDPI

St. Alban-Anlage 66

4052 Basel, Switzerland

This is a reprint of

articles from the Special Issue published online in the open access journal Machines (ISSN

2075-1702) (available at: https://www.mdpi.com/journal/machines/special

issues/smart ![]() manufacturing).

manufacturing).

For citation purposes, cite each article independently as indicated on the article page online and as indicated below:

LastName, A.A.; LastName, B.B.; LastName, C.C. Article Title. Journal Name Year, Volume Number, Page Range.

Cover image courtesy of Zhuming Bi

© 2022 by the authors. Articles in this book are Open Access and distributed under the Creative Commons Attribution (CC BY) license, which allows users to download, copy and build upon published articles, as long as the author and publisher are properly credited, which ensures maximum dissemination and a wider impact of our publications.

The book as a whole is distributed by MDPI under the terms and conditions of the Creative Commons license CC BY-NC-ND.

About the Editors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Zhuming Bi, Lida Xu and Puren Ouyang

Smart Manufacturing—Theories, Methods, and Applications

Reprinted from: Machines 2022, 10, 742, doi:10.3390/machines10090742 . . . . . . . . . . . . . . . 1

Zhuming Bi, Wen-Jun Zhang, Chong Wu, Chaomin Luo and Lida Xu

Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective,

Part I—Digital Triad Concept and Its Application as a System Reference Model

Reprinted from: Machines 2021, 9, 207, doi:10.3390/machines9100207 . . . . . . . . . . . . . . . . 5

Zhuming Bi, Wen-Jun Zhang, Chong Wu, Chaomin Luo and Lida Xu

Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective.

Part II—Systematic Designs of Smart Manufacturing Systems

Reprinted from: Machines 2021, 9, 208, doi:10.3390/machines9100208 . . . . . . . . . . . . . . . . 25

Tama´s B´anyai

Optimization of Material Supply in Smart Manufacturing Environment: A Metaheuristic

Approach for Matrix Production

Reprinted from: Machines 2021, 9, 220, doi:10.3390/machines9100220 . . . . . . . . . . . . . . . . 45

Blockchain-Empowered Digital Twins Collaboration: Smart Transportation Use Case

Reprinted from: Machines 2021, 9, 193, doi:machines9090193 . . . . . . . . . . . . . . . . . . . . . 71

Application of IoT-Aided Simulation to Manufacturing Systems in Cyber-Physical System

Reprinted from: Machines 2019, 7, 2, doi:10.3390/machines7010002 . . . . . . . . . . . . . . . . . 105

Smart Hybrid Manufacturing Control Using Cloud Computing and the Internet-of-Things †

Reprinted from: Machines 2018, 6, 62, doi:10.3390/machines6040062 . . . . . . . . . . . . . . . . 119

Transformation towards a Smart Maintenance Factory: The Case of a Vessel Maintenance Depot

Reprinted from: Machines 2021, 9, 267, doi:10.3390/machines9110267 . . . . . . . . . . . . . . . . 145

A Product Conceptual Design Method Based on Evolutionary Game

Reprinted from: Machines 2019, 7, 18, doi:10.3390/machines7010018 . . . . . . . . . . . . . . . . . 165

Automatic Test and Sorting System for the Slide Valve Body of Oil Control Valve Based on Cartesian Coordinate Robot

Reprinted from: Machines 2018, 6, 64, doi:10.3390/machines6040064 . . . . . . . . . . . . . . . . 183

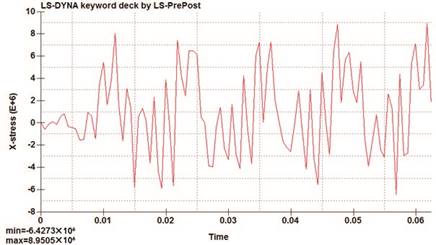

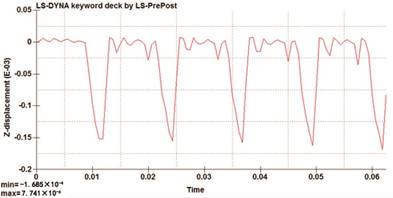

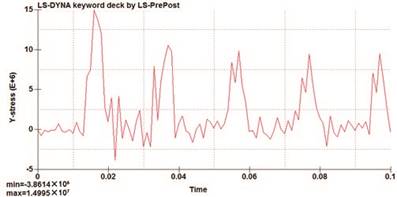

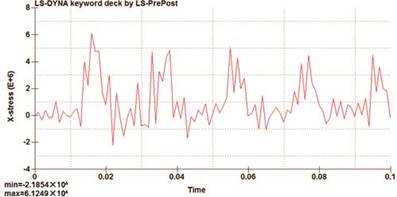

Analysis of Vibration Plate Cracking Based on Working Stress

Reprinted from: Machines 2018, 6, 51, doi:10.3390/machines6040051 . . . . . . . . . . . . . . . . . 197

A Systematic Review of Product Design for Space Instrument Innovation, Reliability, and Manufacturing

Reprinted from: Machines

2021, 9,

244, doi:10.3390/machines9100244 . . . . . . . . . . . .

. . . . 217

Zhuming Bi received the Ph.D. degree from the Harbin Institute of Technology, Harbin, China, and the University of Saskatchewan, Saskatoon, SK, Canada, in 1994 and 2002, respectively. Currently, he is a Professor at the Department of Civil and Mechanical Engineering, Purdue University Fort Wayne (PFW). Professor Bi is the Harris Chair of Wireless Communication and

Applied Research at PFW; he has authored or co-authored 4 books, including three textbooks on ‘Finite Element Analysis Applications’, ‘Computer Aided Design and Manufacturing’, and ‘Digital Manufacturing’. In addition, Professor Bi has published 10 book chapters, 150 journal articles, and over 60 articles in conference proceedings. His research interests are enterprise information systems, digital manufacturing, finite element analysis, machine designs, robotics and automation, and enterprise systems.

Li Da Xu received the B.S. degree in information science from the University of Science and

Technology of China (1978), an M.S. degree in information science from the University of Science and

Technology of China (1981), and a Ph.D. degree in systems science and engineering from Portland

State University, USA (1986). He is an IEEE Fellow, academician of the European Academy of

Sciences (Division of Engineering), academician of the Russian Academy of Engineering (formerly USSR Academy of Engineering), and academician of the Engineering Academy of Armenia. Dr. Xu is a 2016-2021 Highly Cited Researcher in the field of engineering named by Clarivate Analytics (formerly Thomson Reuters Intellectual Property & Science).

Puren Ouyang received his MS and Ph.D. degrees from the University of Saskatchewan of Canada in 2002 and 2005, respectively. Currently, he is an Associate Professor at the Department of Aerospace Engineering, Ryerson University of Canada. His research interests are robotics control, hybrid systems, and mechatronics.

![]()

Editorial

Citation: Bi, Z.; Xu, L.; Ouyang, P.

Smart Manufacturing—Theories,

Methods, and Applications. Machines

2022, 10, 742. https://doi.org/

10.3390/machines10090742

Received: 5 August 2022

Accepted: 8 August 2022

Published: 29 August 2022

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

![]()

Copyright: © 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https:// creativecommons.org/licenses/by/

4.0/).

1 Department of Civil and Mechanical Engineering, Purdue University Fort Wayne, Fort Wayne, IN 46805, USA

2 Department of Information Technology, Old Dominion University, Norfolk, VA 23529, USA

3 Department of Aerospace Engineering, Ryerson University, 350 Victoria St, Toronto, ON M5B 2K3, Canada

* Correspondence: biz@pfw.edu

![]()

Smart manufacturing (SM) distinguishes itself from other system paradigms by introducing ‘smartness’ as a measure to a manufacturing system; however, researchers in different domains have different expectations of system smartness from their own perspectives. In this Special Issue (SI), SM refers to a system paradigm where digital technologies are deployed to enhance system smartness by (1) empowering physical resources in production,

(2) utilizing virtual and dynamic assets over the internet to expand system capabilities,

(3) supporting data-driven decision making at all domains and levels of businesses, or (4) reconfiguring systems to adapt changes and uncertainties in dynamic environments. System smartness is measured by one or a combination of system performance metrics, such as the degree of automation, cost-effectiveness, leanness, robustness, flexibility, adaptability, sustainability, and resilience. This SI aims to present the most representative works in advancing the theories, methods, and applications of SM.

Rapidly developed digital technologies have continuously stimulated shifts of manufacturing system paradigms; most recently, the study of SM has attracted numerous researchers in academia and practitioners in industry [1–5]. However, people in different domains have highly diversified expectations of system smartness, leading to the ambiguity, diversity, and inconsistency of SM concepts in terms of system architecture, reference models, enabling technologies, and evaluation matrices. Bi et al. [6] generalized the definition of SM by unifying diversified expectations of system smartness as customizable measures, and they presented two concepts of digital triad (DT-II) and the Internet of Digital Triad Things (IoDTT) to emphasize the functional requirements (FRs) of SM to accommodate changes and uncertainties in sustainable and cost-effective ways. Bányai [7] analyzed the needs of adaptability and flexibility in matrix production; he argued that flexible manufacturing systems could be the correct solutions to deal with changes in production. He emphasized the importance of effective models and methods in optimizing system controls. In particular, he proposed a hybrid metaheuristic algorithm based on multiphase black hole and flower pollination to plan and schedule manufacturing resources in material handling systems using robots.

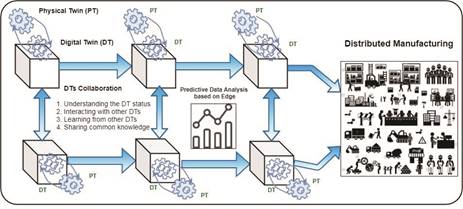

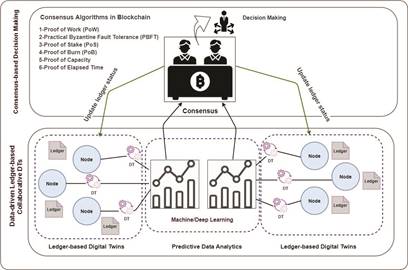

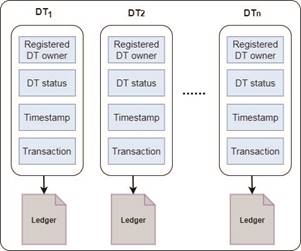

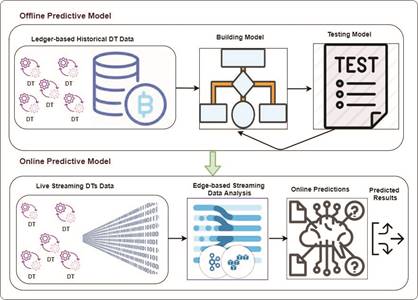

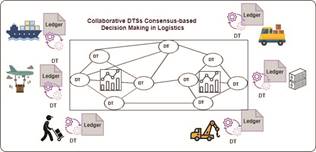

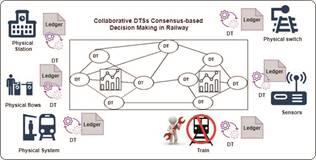

Sahal et al. [8] investigated the roles of digital twins (DTs) in modelling physical assets and supporting decision-making activities in decentralized and distributed manufacturing. They found that DTs required collaboration among stakeholders to reach the consensuses of decisions and predict risks; the critical FRs of collaborations were defined in terms of interoperability, authentication, scalability, and the avoidance of single-point failures. A ledger-based collaborative framework was proposed to fulfill the identified FRs in smart transportation systems, and the incorporated technologies included blockchain technologies (BCTs), predictive analysis techniques, and other digital technologies. Ubiquitous smart things in the Internet of Things (IoT) make it feasible to collect real-time data of the conditions of any manufacturing resources from anywhere at any time; Tan et al. [9] adopted DTs to synchronize and utilize real-time data in a cyber space; the challenges of

![]()

Machines 2022, 10, 742. https://doi.org/10.3390/machines10090742 https://www.mdpi.com/journal/machines

integrating DTs with smart things in IoT were explored, and a new scheme and framework were constructed to simulate DTs with real-time data.

SM has benefited greatly from rapidly developed information technologies, such as DTs, BCT, IoT, cloud computing (CC), big data analytics (BDA), cyber-physical systems (CPSs), and edge-computing. These technologies have been changing the landscape of the research and development of SM radically, in a sense that (1) solutions of acquiring and transferring data become increasingly more affordable in regards to implementing, deploying, and integrating ‘smarter’ things in a system; (2) business-relevant data become increasingly bigger in terms of ‘volume’, ‘variety’, and ‘velocity’, where advanced data analytics can be used to capture, store, process, and utilize data to cope with changes in dynamic environments; (3) the system boundary becomes increasingly vaguer, and system architecture has to be dynamically adaptable to physical and virtual collaborations of business partners over time [10–13].

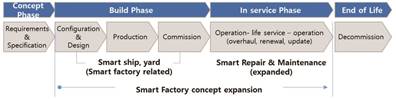

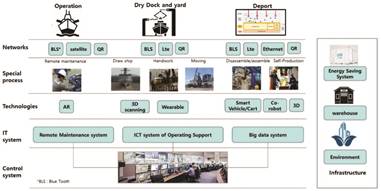

System design methods are used to select system elements, configure these elements into components and systems, and model, evaluate, and compare design options against key performance indicators (KPIs) for system optimization. However, traditional system design methods are mostly for the design of static systems with clear system boundaries. There are needs required for the advancement of system design methods so that a smart manufacturing system can be reconfigurable to achieve high-level smartness in its system lifecycle. The configurations of a smart system must be customized to the constraints of manufacturing resources and the prioritized KPIs. Bi et al. [14,15] proposed a systematic design methodology as the guide for designs of smart manufacturing systems in specified applications. The axiomatic design theory (ADT) was adopted and expanded to design, analyze, and assess smart manufacturing systems, and the applicability of the proposed methodology was verified using three case studies. Erasmus et al. [16] proposed an information architecture to integrate CC and IoT with smart devices for human–robot collaboration; the architecture was modularized for small- or medium-sized enterprises (SMEs) to access extensible cloud services, and it was used as a reference architecture for information management systems in Industry 4.0. The architecture was tested and evaluated with the information systems of ten real-world factories. Kim and Lee [17] extended the SM concept to a maintenance system in ship building and servicing; the framework, procedure, and architecture of a smart maintenance system were developed to systematically design large-scale SM systems.

SM is expected to meet some emerging requirements of automation, adaptability, sustainability, and resilience of modern manufacturing systems in the digital era at numerous aspects, including (1) dealing with any level of system complexity relating to the number and variants of system elements, the interactions of system elements, and anticipated and unanticipated changes over time; (2) maximizing system entropy to adopt changes in a dynamic environment; (3) responding to real-time changes in the shortest possible time; (4) monitoring, diagnosing, and predicting system states and trends, generating preventive solutions for adverse changes, and upgrading systems to adapt preferable changes;

(5) supporting the seamless coordination, collaboration, and cooperation of stakeholders; (6) orchestrating manufacturing resources across enterprise bounds to seize novel opportunities; (7) providing generic architecture applicable to different products, functions, and regions [1,18–20].

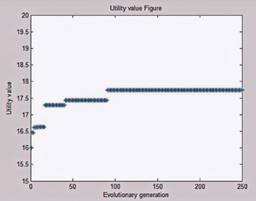

Cutting-edge digital technologies have been widely explored in regard to solving various engineering problems in real-world applications. For examples, Hou et al. [21] developed a function–structure model to evaluate performance and cost in product development; products were characterized in functional and structural domains, respectively, and an evolutionary algorithm (EA) was used to map functions into corresponding structures for the verification of design constrains and the evaluation of design solutions. Kang

Machines

![]()

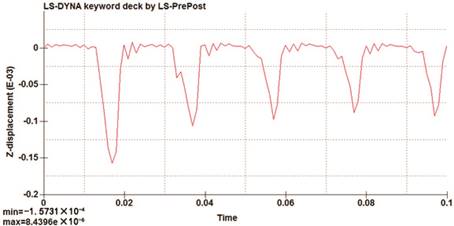

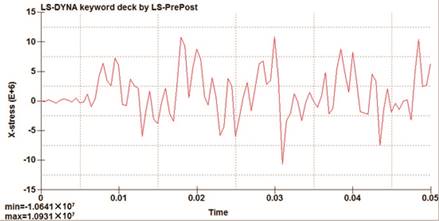

et al. [22] discussed various challenges of using vibrioses to protect the environment during fossil fuel exploration; numerical simulation models were developed to analyze the response of a vibriosis subjected to specific boundary conditions and excitations, and simulation results were used to identify the weakest vibriosis junctions. Liu et al. [23] proposed an integrated robotic system for its application in an ill-structured on-site environment

with the purpose of cost-efficiency. The proposed system consisted of two-terminal manipulators for parallel sorting processes, and it was seamlessly integrated in an automated assembly system to perform sorting tasks consistently in a shortened cycle time. Yung et al. [24] discussed the challenges in designing and manufacturing highly diversified space instruments. The specifications of space instruments were greatly distinguished from those of products on Earth, and careful considerations had to be determined on the size, weight, cost, complexity, and extreme space environments. A systematic literature search method was used to look into the impact of product design and innovation on the development of space instruments; the survey provided important information and critical considerations for using cutting-edge digital technologies in designing and manufacturing space instruments.

Increasingly more manufacturing enterprises are ready to incorporate newly developed technologies, such as DTs, CPSs, IoT, BDA, and BCT, with traditional manufacturing technologies, such as flexible manufacturing systems (FMSs), total quality management (TQM), supply chain management (SCM), enterprise resource planning (ERP), and computer-integrated manufacturing (CIM). However, existing theories, methods, and tools still exhibit limitations in supporting cost-effective vertical integration, decentralization, smart sensing and actuating, autonomy and self-organization, and uses of semantic models [25]. The research of SM in theories, methods, and applications should be advanced to transfer integrated digital technologies into productivity, profitability, and sustainability of systems. This Editorial Team anticipated that future research in SM would mainly incorporate areas of (1) ubiquitous sensing, (2) fusing and integrating data from heterogeneous sources, (3) effective BDA methods, (4) data visualization methods for human interactions, (5) data-driven decision-making supports, (6) workflow composition methods, (7) the standardization and specifications of smart modules, and (8) quantified criteria such as adaptability, sustainability, and resilience for system evaluation [1,6,14].

Acknowledgments: We thank the editors of MDPI for their excellent support to this SI; it would have been impossible without their persistence and great effort. We thank all colleagues who showed an interest in submitting their works and, we especially thank all reviewers for their valuable author recommendations, helping us finalize their high-quality manuscripts; all accepted papers passed a rigorous reviewing process before they were finally accepted and published in the SI. The selected papers represent the quality, breadth, and depth of the study on theories, methods, and applications of SM.

Conflicts of Interest: The authors declare no conflict of interest.

1. Bi, Z.M.; Jin, Y.; Maropoulos, P.; Zhang, W.J.; Wang, L. Internet of things (IoT) and big data analytics (BDA) for digital manufacturing. Int. J. Prod. Res. 2021. [CrossRef]

2. Bi, Z.M.; Xu, L.D.; Wang, C. Internet of things for enterprise systems of modern manufacturing. IEEE Trans. Ind. Inform. 2014, 10, 1537–1546.

3. Bi, Z.M.; Wang, G.P.; Thompson, J.; Ruiz, D.; Rosswurm, J.; Roof, S.; Guandique, C. System framework of adopting additive manufacturing in mass production line. Enterp. Inf. Syst. 2021, 16, 606–629. [CrossRef]

4. Bi, Z.M.; Zhang, W.J. Practical Guide to Digital Manufacturing–First Time-Right from Digital Twin to Physical Twin; Springer International Publishing: New York, NY, USA, 2021; ISBN 978-3-030-70303-5.

5. Bi, Z.M.; Wang, X.Q. Computer Aided Design and Manufacturing (CAD/CAM); Wiley: New York, NY, USA, 2020.

6. Bi, Z.; Zhang, W.-J.; Wu, C.; Luo, C.; Xu, L. Generic design methodology for smart manufacturing systems from a practical

Perspective, part I—Digital triad concept and Its application as a system reference model. Machines 2021, 9, 207. [CrossRef]

7. Bányai, T. Optimization of material supply in smart manufacturing environment: A metaheuristic approach for matrix production. Machines 2021, 9, 220. [CrossRef]

8. Sahal, R.; Alsamhi, S.H.; Brown, K.N.; O’Shea, D.; McCarthy, C.; Guizani, M. Blockchain-Empowered digital twins collaboration: Smart transportation use case. Machines 2021, 9, 193. [CrossRef]

9. Tan, Y.; Yang, W.; Yoshida, K.; Takakuwa, S. Application of IoT-Aided simulation to manufacturing systems in cyber-physical system. Machines 2019, 7, 2. [CrossRef]

10. Wang, C.; Bi, Z.M.; Xu, L.D. IoT and cloud computing in automation of assembly modeling systems. IEEE Trans. Ind. Inform. 2014, 10, 1426–1434. [CrossRef]

11. Wang, L.; Xu, L.D.; Bi, Z.M.; Xu, Y. Data cleaning for RFID and WSN integration. IEEE Trans. Ind. Inform. 2014, 10, 408–418. [CrossRef]

12. Viriyasitavat, W.; Xu, L.D.; Bi, Z.M. User-oriented selections of validators for trust of internet-of thing services. IEEE Trans. Ind. Inform. 2022, 18, 4859–4867. [CrossRef]

13. Viriyasitavat, W.; Xu, L.D.; Bi, Z.M. Blockchain-based business process management framework for service composition in industry 4.0. J. Intell. Manuf. 2020, 31, 1737–1748. [CrossRef]

14. Bi, Z.; Zhang, W.-J.; Wu, C.; Luo, C.; Xu, L. Generic design methodology for smart manufacturing systems from a practical perspective. part II—Systematic designs of smart manufacturing systems. Machines 2021, 9, 208. [CrossRef]

15. Bi, Z.M.; Zhang, W.J.; Wu, C.; Li, L. New digital triad (DT-II) concept for lifecycle information integration of sustainable manufacturing systems. J. Ind. Inf. Integr. 2022, 26, 100316. [CrossRef]

16. Erasmus, J.; Grefen, P.; Vanderfeesten, I.; Traganos, K. Smart hybrid manufacturing control using cloud computing and the internet-of-things. Machines 2018, 6, 62. [CrossRef]

17. Kim, G.S.; Lee, Y.H. Transformation towards a smart maintenance factory: The case of a vessel maintenance depot. Machines 2021, 9, 267. [CrossRef]

18. Viriyasitavat, W.; Bi, Z.M.; Hoonsopon, D. Blockchain technologies for interoperation of business processes in smart supply chains. J. Ind. Inf. Integr. 2022, 26, 100326. [CrossRef]

19. Viriyasitavat, W.; Xu, L.; Dhiman, G.; Sapsomboon, A.; Pungpapong, V.; Bi, Z.M. Service workflow: State-of-the-Art and future trends. IEEE Trans. Serv. Comput. 2022. [CrossRef]

20. Bi, Z.M.; Chen, B.; Xu, L.D.; Wu, C.; Malott, C.; Chamberlin, M. Enterline, T. Security and safety assurance of collaborative manufacturing in industry 4.0. Enterp. Inf. Syst. 2022. [CrossRef]

21. Huo, Y.-L.; Hu, X.-B.; Chen, B.-Y.; Fan, R.-G. A product conceptual design method based on evolutionary game. Machines 2019, 7,

18. [CrossRef]

22. Kang, Z.; Li, G.; Wang, F.; Zhang, H.; Su, R. Analysis of vibration plate cracking based on working stress. Machines 2018, 6, 51. [CrossRef]

23. Liu, P.; Li, G.; Su, R.; Wen, G. Automatic test and sorting system for the slide valve body of oil control valve based on cartesian coordinate robot. Machines 2018, 6, 64. [CrossRef]

24. Yung, K.-L.; Tang, Y.-M.; Ip, W.-H.; Kuo, W.-T. A Systematic review of product design for space instrument innovation, reliability, and manufacturing. Machines 2021, 9, 244. [CrossRef]

25. Dotoli, M.; Fay, A.; Miskowicz, M.; Seatzu, C. An overview of current technologies and emerging trends in factory automation. Int. J. Prod. Res. 2019, 57, 5047–5067. [CrossRef]

![]()

Article

Citation: Bi, Z.; Zhang, W.-J.; Wu, C.;

Luo, C.; Xu, L. Generic Design

Methodology for Smart

Manufacturing Systems from a

Practical Perspective, Part I—Digital

Triad Concept and Its Application as a System Reference Model. Machines

2021, 9, 207. https://doi.org/

10.3390/machines9100207

Academic Editors: Angelos

P. Markopoulos and Ibrahim

Nur Tansel

Received: 26 July 2021

Accepted: 20 September 2021

Published: 23 September 2021

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

![]()

Copyright: © 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https:// creativecommons.org/licenses/by/

4.0/).

1 Department of Civil and Mechanical Engineering, Purdue University Fort Wayne, Fort Wayne, IN 46805, USA

2 Department of Mechanical Engineering, University of Saskatchewan, Saskatoon, SK S7N 5A9, Canada; Chris.Zhang@usask.ca

3 School of Economics and Management, Harbin Institute of Technology, Harbin 150001, China

4 Department of Electrical and Computer Engineering, Mississippi State University, Starkville, MS 39762, USA; chaomin.luo@ece.msstate.edu

5 Department of Information Technology, Old Dominion University, Norfolk, VA 23529, USA; lxu@odu.edu * Correspondence: biz@pfw.edu (Z.B.); wuchong@hit.edu.cn (C.W.)

Abstract: Rapidly developed information technologies (IT) have continuously empowered manufacturing systems and accelerated the evolution of manufacturing system paradigms, and smart manufacturing (SM) has become one of the most promising paradigms. The study of SM has attracted a great deal of attention for researchers in academia and practitioners in industry. However, an obvious fact is that people with different backgrounds have different expectations for SM, and this has led to high diversity, ambiguity, and inconsistency in terms of definitions, reference models, performance matrices, and system design methodologies. It has been found that the state of the art SM research is limited in two aspects: (1) the highly diversified understandings of SM may lead to overlapped, missed, and non-systematic research efforts in advancing the theory and methodologies in the field of SM; (2) few works have been found that focus on the development of generic design methodologies for smart manufacturing systems from the practice perspective. The novelty of this paper consists of two main aspects which are reported in two parts respectively. In the first part, a simplified definition of SM is proposed to unify the existing diversified expectations, and a newly developed concept named digital triad (DT-II) is adopted to define a reference model for SM. The common features of smart manufacturing systems in various applications are identified as functional requirements (FRs) in systems design. To model a system that is capable of reconfiguring itself to adapt to changes, the concept of IoDTT is proposed as a reference model for smart manufacturing systems. In the second part, these two concepts are used to formulate a system design problem, and a generic methodology, based on axiomatic design theory (ADT), is proposed for the design of smart manufacturing systems.

Keywords: smart manufacturing; information technologies (IT); system of systems (SoS); digital manufacturing (DM); digital twins (DT-I); digital triad (DT-II); cyber-physical systems; Internet of Things (IoT); Internet of Digital Triad Things (IoDTT); big data analytics (BDA); cloud computing

(CC); axiomatic design theory (ADT)

![]()

Machines 2021, 9, 207. https://doi.org/10.3390/machines9100207 https://www.mdpi.com/journal/machines

of—and changes to—the manufacturing environment, and the manufacturing industry has entered the digital era, due to the adoption of advanced information technologies and operation technologies [6].

The historical advancement of manufacturing technologies has been widely discussed [7,8], and the following trends have become common sense to researchers in manufacturing: (1) products become increasingly advanced, diversified, and with fragmented demand; (2) global manufacturing capabilities become saturated in comparison to customers’ needs, and manufacturing enterprises face ever-increasing competitions regionally and globally; (3) the scope and complexities of manufacturing businesses are continuously increased, and this forces enterprises to adopt more advanced technologies to automate manufacturing operations and decision making in various domains and levels of business; (4) the boundaries of manufacturing systems become vague and dynamic, since enterprises have to collaborate with others to make complex products or systems; (5) manufacturing systems are expected to be optimized against more performance metrics, including functionality, quality, productivity, cost, lead-time, personalization, adaptability, and sustainability; (6) the businesses of manufacturing systems are gradually extended to cover all the stages of product lifecycles, from raw materials to the disposal of used products; (7) manufacturing technologies have advanced from human operation to automation, from disciplinary to multidisciplinary, from standalone to integrated and comprehensive, and from sophisticated to adaptable and reconfigurable.

Since the advances in manufacturing technologies can be characterized by the degree of automation (of either (1) manufacturing processes or (2) the decision making support at different domains and levels of system operations), information technologies (IT) have played indispensable roles in advancing manufacturing technologies. Every leap in the manufacturing paradigms was triggered by the corresponding IT; to name a few, mechanization and electronic and electrical controls for mass production, numerical controls (NC) or computer NC (CNC), networking, and group technologies (GT) for flexible manufacturing systems (FMS), computer aided design and manufacturing (CADM), material resource planning (MRP), and enterprise resource planning (ERP) for computer integrated manufacturing (CIM), quality control (QC) and total quality management (TQM) for lean production (LP), product data management (PDM), product lifecycle management (PLM), and enterprise systems (ES) for agile manufacturing (AM), business process management (BPM), service-oriented architecture (SoA), and agent-based techniques for virtual manufacturing (VM), and Internet of Things (IoT), radio frequency identification (RFID) [9–11], cyber-physical systems (CPS), human-cyber-physical systems (HCPS), blockchain technology (BCT), big data analytics (BDA), and cloud computing (CC) for digital manufacturing (DM) and smart manufacturing (SM) [3,4]. The studies in DM have attracted a great deal of attention recently. For example, Dey et al. [12,13] investigated the impacts of optimized autonomation policies on the control variables in the inventory management of a smart production system. In the digital era, the digitization of manufacturing businesses has progressed exponentially, and the increasing adoption of digital technologies in our economy has reshaped the way we live and work. The trend of digitization has brought new opportunities and challenges for manufacturing enterprises to gain business competitiveness over their strategical competitors in the globalized market [14,15]. The further development of the digital economy in the near future will be characterized by four dimensions of smartness: smart manufacturing, smart products and services, smart supply chains, and smart processes [16].

SM or DM have become the frontier in advancing manufacturing technologies [17]. However, today’s manufacturing systems are, in fact, systems of systems, due to the high-level of system complexity, the large variety of manufacturing assets and enabling technologies, and the dynamics of systems over time. This causes diversity and confusion for practitioners in understanding SM and its relevant concepts, reference models, performance matrices, and the selection of design methodologies. On the one hand, any manufacturing system should be a sophisticated system tailored to the given manufacturing resources, markets, and business environment, and there is no universal SM solution for enterprises. On the other hand, manufacturing businesses are involved with the transformation of materials, values, information, and knowledge of multiple disciplines, and system performances are assessed very differently in these disciplines. In other words, the stakeholders of one manufacturing system have different expectations of SM, which might be correlated, coupled, or even conflicted with each other.

The authors are highly motivated to gain a thorough understanding of the state of the art development of smart manufacturing (SM) systems and to identify the direction of future research in the field of SM. The main contributions from the reported work are as follows:

(1) It is found that the existing works on SM show the limitations of at two aspects, i.e., (a) the highly diversified understandings of the functionalities and expectations of SM that may result in overlapped, missed, or non-systematic research efforts in advancing the theory and methodologies in the field of SM; (b) few works have been published that propose a generic design methodology for the design of smart manufacturing systems in practice.

(2) The definition of SM is simplified to unify the diversified expectations. A newly developed concept, digital triad (DT-II), is adopted to define a reference model for SM; it reflects all of the main characteristics of digital solutions at the different levels and domains of system operations.

(3) The common features of various smart manufacturing systems are identified; particularly, the concept of IoDTT is proposed as a reference model to represent the need for system reconfiguration in the event of uncertainties and changes in business environments.

(4) The generality and specialty in designing and implementing various smart manufacturing systems are discussed, to illustrate the need for developing a general design methodology to guide the design of a smart manufacturing system from a practical perspective.

The remainder of paper is organized as follow. In Section 2, an overview of SM and its development is provided, to understand the limitations of the existing works. In Section 3, the concept of SM is refined, and the corresponding reference model is proposed, using the concept of digital triad (DT-II). In Section 4, the design of a modular robotic system is used as an example to illustrate the system design problems at different phases, and the generality of designing and implementing tailored smart systems is discussed, to highlight the need for generic design methodologies. In the following part II of this work, two proposed concepts are adopted for formulating system design problems, and ADT is suggested as the generic design methodology for SM. Three case studies are introduced to illustrate the application of the proposed design methodology, and the future research directions regarding SM are discussed as a summary.

2.1. Original Definition and Variations

Smart manufacturing (SM) is also commonly referred to as “Industry 4.0” in Europe and “Made in China 2025” in China, as the latest iteration of the industrial revolution that began 260 years ago. The recent development of information technologies (IT) has provided the concrete foundation to revolutionize manufacturing in the form of SM [18]. The concept was coined by the National Science Foundation (NSF) at its workshop on cyberinfrastructure in 2006 [19]. SM was originally defined as a fully integrated and collaborative manufacturing system that responds in real time to meet the changing demands and conditions in the factory, the supply chain, and customer needs [20,21]. The vision and goals of SM were then developed by the Smart Manufacturing Leadership Coalition in 2011 [22]. The roadmaps and standards for Industry 4.0 and SM were firstly developed by the German Commission for Electrical, Electronic & Information Technologies [23] in 2014 and the National Institute of Standards and Technology (NIST) in 2016 [20], respectively.

The clean energy smart manufacturing innovation institute (CESMII) was created to promote SM as a sustainable driving force for manufacturing in the United States to adopt smart sensors, controls, platforms, and models in 2016. The closely related concept, Made in China 2025, was initialized to advance the independent manufacturing technologies in China in 2015 [24]. From the perspective of applications, SM refers to an IoT-based application to automate manufacturing processes and utilize data analytics tools to improve the performances of manufacturing systems. SM uses information technologies, computer-integrated technology, flexible workforces, and digital technology to improve the system adaptability for the changes and uncertainties in system operations [25]. SM was treated as an application of Industry 4.0 in manufacturing, where advanced IT, such as the Internet of Things (IoT), cyber physical systems (CPS), machine learning (ML), additive manufacturing (AM), and robotics, were used in process automation and decision making support [26]. It should be noted that Industry 4.0 refers to a system in which automated facilities are networked, so that data can be collected, processed, and utilized to make smart decisions in system operations.

SM distinguishes itself from other manufacturing paradigms by defining the meaning of “smart”, whereas researchers in different disciplines and roles define different expectations of smartness. For example, the smartness of a manufacturing system, according to Romero et al. [27] covers (1) the ability to communicate to exchange data, and to collect and report data regarding the state of manufacturing assets; (2) the embedded knowledge for the representation of human expertise and the understanding of system elements and environments; (3) learning capabilities through the application of diversified algorithms, methods, and tools; (4) reasoning capabilities for data-driven decision making; (5) the perception capability to sense, understand, and respond to environmental changes; (6) control capabilities to ensure smooth manufacturing processes, and to make and deliver products to end-users; (7) self-organization to reconfigure systems to accommodate changes and uncertainties; (8) context awareness that retrieves the information and knowledge that characterizes the state of the systems and environments. Lenz et al. [28] extended the scope of SM to the collection of raw materials; the data in the entire product lifecycle was acquired and processed to improve the accuracy and reliability of the process signatures and to improve manufacturing processes. Filleti et al. [29] used a grinding unit as an example to discuss the impact of manufacturing processes and real-time monitoring on the performance of production and environmental indicators. The manufacturing assets were mostly developed with assured safety and security at the device level; security assurance became a critical challenge when the manufacturing assets were interactive and interoperative. In addition, Maggi et al. [30] and Viriyasitava et al. [31–35] emphasized the importance of addressing cybersecurity awareness regarding the configuring systems, to adjust to changes and uncertainties in dynamic business environments.

Felice et al. [36] proposed a bibliometric model for analyzing the existing works on SM from 2011 to 2018; their objectives were to identify relevant topics and explore the interdependencies of these topics. It was found that researchers generally expected SM to improve the efficiency, cost-effectiveness, safety, and sustainability of systems, and the main enabling technologies for SM were automation, IoT, CPS, BDA, cloud computing (CC), modelling and simulation, and additive manufacturing (AM). SM integrated manufacturing assets, sensors, technological platforms, networks, data-driven modelling, simulations, decision making, and diagnoses and predictions to improve efficiency, flexibility, adaptability, and resilience [37,38]. With the trend of digitization, SM becomes the new frontier of manufacturing systems [17]. SM, as a flexible system, should be able to self-optimize performance across a broader network, self-adapt to change and learn from new conditions in real or near-real time, and autonomously run entire production processes.

2.2. Main Characteristics

The five main characteristics of SM identified by Deloitte (2021) are that they are:

(1) connected to all smart things through the internet, including traditional datasets, realtime data enabling collaboration, and the collaborations across departments; (2) optimized for predictable capacities, increased asset uptime and efficiency, highly automated production and material handling, and minimized cost; (3) transparent for live metrics and tools, and have real-time linkages to demand forecasts and order tracking; (4) proactive for anomaly identification and resolutions, restocking and replenishment, and the identification of quality issues; (5) agile for flexible and adaptable scheduling and production changes, with configurable machines and layouts. SM was expected to improve the efficiency of manufacturing assets, improve the quality of products and manufacturing processes, reduce the cost of system operations, and to increase the safety and sustainability of products, manufacturing processes, systems, and human living environments. SM was characterized as networked, big data, digitization, data-driven, resource sharing, connected, sustainable and resilient; in particular, sustainability and resiliency distinguished SM from other manufacturing paradigms [39].

SM, as an engineering system, was compared to a biological system by Byrne et al. [40], and it was suggested that SM should be the convergence of biology and SM, as part of the evolution of the system paradigms involved in bio-inspiration, bio-integration and bio-intelligence. Therefore, SM would incorporate components, features, characteristics, and capabilities to converge a manufacturing system with a biological system. SM is a type of intelligent manufacturing (IM) system, although it is certainly at a more advanced level of intelligence in comparison to traditional IM. Wang et al. [41] elaborated the differences between SM and IM in detail, and they argued that SM was a comprehensive outcome of integrating an increasing number of digital tools with an intelligent manufacturing system. IM and SM were closely correlated; indeed, the differences were mainly in qualitative and quantitative measures, and SM was seen as the advanced stage of IM.

2.3. Technological Drivers

Manufacturing paradigms are enabled by the available technologies, particularly information technologies in the digital era. Kulvatunyou et al. [42] analysed the development of the standards for the integration of semantic data and concluded that the standards for digital manufacturing must be advanced to maintain, represent, and present data in the form of knowledge and insight for collaborative decision making support. It is well known that the digital transformation from Industry 3.0 to 4.0 was enabled by some critical ITs, such as IoT, CC, BDA, and AI [16]. IoT enables the connection of everything in manufacturing, in the same way as Industrial IoT (IIoT); in return, IIoT supports the new and unprecedented interactions among the hardware, software, virtual assets, and humans. In addition, IIoT can be integrated with AI for enterprises to increase their flexibility, agility, efficiency, and resilience [21].

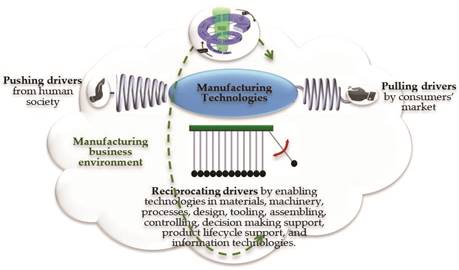

Bi and Zhang [3] classified technical drivers into three types, as shown in Figure 1. From the perspective of system inputs, manufacturing businesses are pushed by humans’ expectations for civilization and continuous development. From the perspective of system outputs, manufacturing businesses are pulled by users’ demand for better and more products. From the perspective of system transformation, manufacturing processes are gradually advanced by integrating an increasing number of relevant technologies through the iteration of continuous improvement (CI). For system transformation, the trends of the reciprocating drivers were (1) the increasing decentralization of the manufacturing businesses, (2) additive manufacturing using polymeric, metallic, and bio-materials, (3) networks and the integration of supply chains, (4) cyber security assurance, (5) the elimination of latency, (6) high-level automation and self-optimization, (7) the unprecedented scale and level of connections, (8) the adoption of advanced artificial intelligence and machine learning, (9) the sustainability of products, processes, and systems, and (10) the expectations of responsiveness, robustness, and residence [40].

Figure 1. Three types of technological drivers in manufacturing (Reprinted with permission from ref. [3]. 2021, Springer Nature).

SM relies on the integration of various digital technologies. Ghobakhloo [14] argued that digitization was attributed to the information technologies that are used for decentralization, horizontal and vertical integrations, interoperability, virtualization, and modularity.

Modularity was viewed as one of the most effective ways to deal with the complexity, changes, and uncertainties in a dynamic environment, and the idea of modularity was applicable to both internal and external manufacturing assets [43]. The virtual assets were used for servitization, and the corresponding manufacturing system was referred to as a product-service system. Brad and Murar [44] discussed the business model, economic impact, and reconfiguring technologies of a product-service system. Feldner and Herber [45] evaluated the communication protocol of IPv6 to support the interactions and interoperations of networked things. Kumar [46] discussed the impact of IoT, CPS, human– robot interaction (HRI), and augmented reality (AR) on the development of new materials and manufacturing processes in SM. Innovation in digital technologies led to advances in new materials and manufacturing processes. SM became practical due to rapidly growing technologies, the ever-increasing complexity of the supply chains, the global fragmentation of production and demands, the growing pressure of competitiveness from unexpected sources, organizational realignment caused by the marriage of information technologies and organization technologies, and ongoing talent challenges [17]. Standardization is powerful in developing and implementing advanced manufacturing technologies. For the seamless integration of various manufacturing assets, the efforts regarding standardization are indispensable. Leading standards organizations, such as the International Organization for Standardization (ISO), National Institute of Standards and Technology (NIST), International Telecommunication Union (ITU), and Institute of Electrical and Electronics Engineers (IEEE), have developed the standards for the architecture, reference models, and frameworks of smart manufacturing [5,18,20,21].

2.4. Applications

The manufacturing industry has a strong impact on the anthropogenic environment; with the growing concern regarding the deterioration of the environment, SM must expand its business scope to the entire product lifecycle by recycling, reusing, and remanufacturing to promote circular economy. Barletta et al. [47] considered the bounds of distinguishing products and services as the environmental breakeven points that could be determined by environmental assessment. Blomeke et al. [5] proposed a recycling 4.0 framework with integrated SM technologies and solutions to support recycling, reusing, and remanufacturing. Jaspert et al. [48] referred to the reconfiguration of SM as smart retrofitting, and an SM could be retrofitted at any functional layer of an enterprise, from the physical, sensor, connectivity, and data layers, to the application layer. Most of the reported applications were in the preliminary stages and met the expectations only for certain aspects. For example, Zenisek et al. [49] introduced an experimental SM system with integrated mixed reality and additive manufacturing for predictive maintenance, and they identified challenges in data merging, online applicability, the conflict of reactivity and false positive rates, and shortfalls in customers’ other expectations.

Rodger et al. [50] discussed the need for sustainability in highly automated car body manufacturing; existing methods and algorithms were surveyed to identify the bottlenecks for improving the sustainability of manufacturing systems from the perspective of product lifecycles. Siiskonen et al. [51] explored the potential application of SM in producing personalized medicines; however, they limited this to the synergic outcomes by integrating the platforms for the design of products and manufacturing processes. They found that customer satisfaction was improved by modularized table designs at increased production costs. Ghobakhloo and Ching [15] surveyed the application of digital technologies in smalland medium-sized enterprises (SMEs); they found the use of SM in SMEs was restrained, due to technological, organizational, and environmental factors. Kamble et al. [52] investigated the application of SM in India’s automotive industry, and the benefits of SM were assessed across 10 dimensions (i.e., quality, cost, time, flexibility, integration, productivity, computing, sustainability, diagnosis, and prognosis).

2.5. Limitations of Existing Works

Despite its great potential, numerous researchers discussed the limitations of the existing works on SM. For example, Phuyal et al. [53] analyzed the technological gaps in adopting state of art IT in smart manufacturing systems. Their main concerns were the maturity and readiness of these technologies (i.e., AI, CPS, BDA, AR, IoT, and robotic technologies) in achieving tangible expectations in real-world industrial applications.

Others discussed the challenges regarding the integration and complexity of systems.

SM integrates many newly developed manufacturing technologies in systems. While advanced technologies are generally complex, a system that is poorly or inappropriately designed for a particular application is not expected to benefit enterprises. Uysal and Mergen [54] expressed concern over the sharing and integration of data across systems and products, and discussed the feasibility of using an intelligent digital mesh (IDM) to form a system made up of dynamically interconnected elements. SM aims for a high level of automation with minimized human effort in collecting, transferring, processing, and mining data. However, the relevant studies were mostly fragmented by focusing on one or a small number of issues, such as decision making, cyber–physical interactions, information infrastructures, digitalization, human–machine interactions, cloud computing, and virtual services [55], and generalizability was lacking from system perspectives. For example, a smart manufacturing system focused on the utilization of hardware assets may undervalue the impact of these assets on system-level performances. To improve the agility and adaptability of SM, advanced methods and tools are needed to connect digital technologies and their business goals for cost effectiveness [56].

The cost of a smart manufacturing system is another significant downside. This is particularly true for small to midsize enterprises (SMEs). Over 95% of enterprises are SMEs that lack manufacturing assets, other than their core competencies for new business opportunities. SMEs were not able to afford the considerable expense for the advanced technology, since short-term benefits were mostly prioritized, and the savings over the long term would outweigh the startup costs. Although the gaps regarding the adoption of digital technologies by SMEs were discussed [37,38], limited works were found that focused on the development of roadmaps and system frameworks for assessing the maturity and readiness of SMEs to adopt digital technologies.

A set of the performance metrics are used to compare and optimize systems. Helu et al. [57] indicate that there are limitations in the assessment of the performances of adopted digital technologies; since the evaluation relies on an appropriate model for the breadth and depth of the technologies that were usually unavailable. Quantitative measures are essential to develop the systematic design methodologies of manufacturing systems. However, the existing assessment models, methods, and criteria are mostly empirical, and built on numerous assumptions and hypotheses; manufacturing systems are viewed as black or grey boxes, and system performances are mainly evaluated based on system inputs and outputs, with the limited context of value-added and non-value-added manufacturing processes in systems [58]. Most models lack consistent data, reliable analysis methods, and user-friendly tools for decision makers to assess system performance in an understandable way [59]. The performance assessment methods fail to match advanced technologies to market demands in manufacturing [60]. Few methods were available to design and evaluate system configurations and implement a smart manufacturing system based on a set of the specified assessment metrics. Despite the large variety of available performance metrics, the importance of selecting the right metrics was overlooked, and no coherent framework was available to adequately measure the effectiveness of system configurations [61].

Despite its attractiveness, the research topic of SM is relatively new, and the relevant studies are mostly preliminary. From the perspective of its applications, the existing works on SM show the following limitations.

SM tends to pursue a full wish list of the functional requirements of the traditional manufacturing paradigms, including automation, productivity, leanness, flexibility, agility, sustainability, adaptability, and resilience. While it is reasonable to represent system expectations from different perspectives, system complexity will easily become unmanageable when designing and controlling a smart manufacturing system. Moreover, the resulting system might not be optimized, since many performance metrics conflict with each other, and the most critical metrics for the weakest aspects must be emphasized.

SM emphasizes (a) the necessities of digital technologies, (b) networking and virtual assets, and (c) adaptability to environmental changes and uncertainties. However, in the existing definitions of SM, the uniqueness of digital technologies was not distinguished from those of other advanced technologies, or from the representations of all advanced technologies in traditional manufacturing paradigms. Additionally, there is no mechanism to distinguish fixed/dynamic, internal/external, and physical/virtual resources, as well as their corresponding roles in systems’ lifecycles. Lastly, SM was still modelled as a system with stable structures (commonly known as a hierarchical or multidimensional grid structure), which is ineffective in representing system configurations that are intended to adapt to changes and uncertainties over time. There are some conflicts among steady system models, system reconfiguration, and the adaptability over system lifecycles [3,4].

Other than some discussions on enabling technologies, system architecture, reference models, and performance metrics, no systematic methodology has been explored in designing a smart manufacturing system. The existing examples of smart manufacturing systems were conceptual and lacking in details of system developments.

The available performance metrics were highly diversified. Moreover, most of the metrics limited their applications to system designs only, since the quantifications were data-driven and made for black box or gray box systems. It should be noted that, during the phase of system design or reconfiguration, an evaluation model should be a white box and should represent the dependencies of the performance metrics (such as the level of automation, configurability, and residence) on the design variables (such as the selection of system elements, and the assembly and interaction of system elements) directly.

In good manufacturing practices, any manufacturing system must be tailored to a specified application, and the same applies for a smart manufacturing system. Therefore, it is our argument that SM is better defined to satisfy the most common system requirements, rather than all requirements, which might be optional, of less importance, and tailored to specific applications. Based on a generic definition of SM focusing on its core values, a reference model can be derived to develop a systematic methodology for the designs of SM. In this section, a new definition of SM is proposed, and the rationales of this proposal are provided by (1) identifying the common features of SM as functional requirements (FRs), (2) adopting two new concepts, DT-II and IoDTT, as the design solutions (DSs) for the given FRs, and (3) discussing the solutions for the limitations of the existing works identified in Section 2.

3.1. New Definition of SM

We propose to redefine SM and clarify the relevant concept of smartness as follows:

“Smart manufacturing (SM) is a type of manufacturing paradigm for the enhanced smartness of systems, in which digital technologies are used to empower the physical things in manufacturing products, access virtual assets over networks for expanded manufacturing capabilities, support data-driven decision making in any domain and at any level of manufacturing operations, and reconfigure systems to adapt to the changes in customer needs when making products”.

“The smartness of a manufacturing system refers to its ability to (1) offer better manufacturing processes or (2) support better decision making in other manufacturing operations. Smartness can be measured by one, or a combination of, system performance metric(s), such as the degree of automation, cost-effectiveness, leanness, robustness, flexibility, adaptability, sustainability, and resilience”.

In comparison to the existing definitions of SM, the proposed definition is generic and applicable to any smart system that adopts digital technologies and is capable of using virtual resources and reconfiguring systems. More importantly, the proposed definition considers the continuous improvement (CI) of system smartness at any increment, domain and level, rather than the overall system-level performance of everything with unmanageable complexity.

3.2. Functional Requirements (FRs) of SM

We are interested in developing a generic model for the system elements in SM. Therefore, the core values of SM with its new definition are treated as functional requirements (FRs). Consequently, a new representation of a generic system element must meet the following FRs.

FR1—Performing manufacturing processes: a manufacturing system transforms raw materials into the final products through a series of manufacturing processes in the material flows of systems. Manufacturing processes are performed on physical manufacturing assets. Therefore, making products (FR1) is the primary FR of a manufacturing system, and it should be defined based on the variants and volumes of products that customers need. In addition, since a complex product involves many parts and components that are made using different manufacturing processes, physical manufacturing assets can be defined for the products, components, parts, and processes. For the purpose of generality, one physical entity is involved in one system element; such a physical entity can be present at any level of the product, from a specific process, part, component, product, product family, or product series over its lifecycle.

FR2—Dealing with changes in customer needs in manufacturing processes: a smart manufacturing system is sustainable; it is capable of reconfiguring itself to deal with the changes in customers’ needs, as well as the disturbances and uncertainties in manufacturing environments. Customers’ needs correspond to the functionalities, variations, volumes, delivery times, and other expectations of products that change in the market over time. The solutions for a system model to adapt to changes are (1) the software flexibility of adjustable assets, (2) the hardware modularity, which is capable of configuring the system by selecting different modules and assembling them in different ways, and (3) the combination of software and hardware flexibility [43].

FR3—Supporting virtual analyses of manufacturing processes: to perform a manufacturing process successfully, engineers must define, plan, program, verify, validate, control, and monitor the process to ensure it is carried out correctly the first time. With the ever-increasing complexity of manufacturing processes, performing these complex tasks is far beyond manual effort. In SM, digital models are developed as digital twins (DT-I) of the corresponding physical assets; digital twins are utilized for the optimization, simulation, and verification of manufacturing processes, and for controlling, monitoring, and diagnosing manufacturing processes in actual operations.

FR4—Acquiring, processing, and mining data for use in digital models: maintaining a manufacturing system involves numerous decision-making activities at all levels, domains, and aspects of businesses. On the other hand, SM emphasizes responsiveness, adaptability, and resilience to the changes and uncertainties in dynamic environments. Therefore, decision-making activities are closed-loop and data-driven processes that rely on reliable and abundant data about everything in the system. Physical assets, in SM, are intended to acquire real-time data; they are networked to collect and share data, and the collected data is processed, mined, and utilized by digital models for decision making support.

FR5—Making decisions for enhanced system smartness: the decisions for manufacturing operations are made based on the data collected from machines, operators, sensors, suppliers, markets, and users. Due to the rapid growth in networked elements in a system, decision-making activities about manufacturing operations usually involve exceptionally large data sets that are characterized as big data in terms of variety, volume, velocity, veracity, and value (5V). Big data is analyzed and mined to allow smarter decisions to be made regarding manufacturing operations, and to achieve better system performance for any aspects of interest, such as agility, robustness, adaptability, flexibility, and resilience.

FR6—Accessing virtual resources: the scope of manufacturing businesses has been continuously increased due to the growing complexity of products and the need for manufacturing businesses to extend over product lifecycles. Manufacturing systems are highly pressured by having to reconfigure themselves to meet the changes in customer needs over time. Virtual manufacturing resources become increasingly important for the host enterprises to cover the increasing scope of manufacturing businesses [8]. The information infrastructure of an enterprise system (ES) should be capable of accessing virtual resources and supporting the interactions and interoperations of internal and external resources seamlessly.

FR7—Supporting decision making for incorporation-level businesses: in the digital era, manufacturing systems become increasingly distributed and decentralized, and manufacturing businesses within a system become more closely related to the stakeholders, such as suppliers, service providers, logistic systems, and users, across the boundaries of the system. Therefore, sustainable manufacturing operations require numerous decision-making processes at the incorporation-level, such as the selection of suppliers or service providers, the composition of workflows for emerging business opportunities, and the reconfiguration of systems or virtual enterprise alliances to adapt to changing customer needs. Decision making support systems should be able to deal with the incorporation-level big data to support the interactions and interoperations of enterprises with assured security, privacy, and responsiveness [31–35].

3.3. Generic Model of System Elements—Digital Triad (DT-II)

A system can generally be modelled by (1) a set of system elements, (2) the relations between system elements, (3) a series of the transformation from the inputs to the outputs of the system, and (4) a set of the performance metrics that are quantified based on (1), (2), and (3). Modelling a system begins with the representation of the system’s elements.

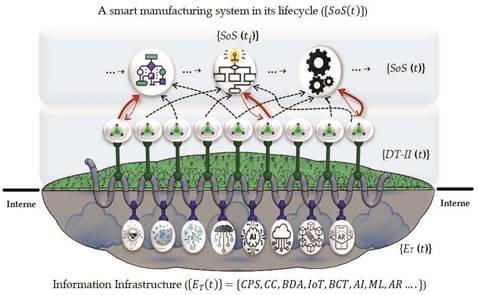

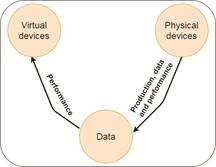

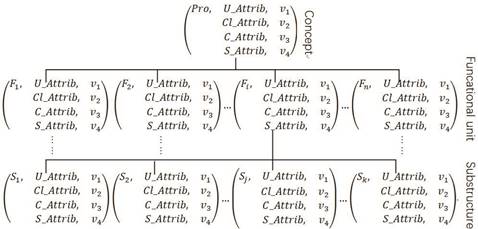

A smart manufacturing system is, in fact, a system of systems (SoS). SM is a multiplicity of technologies and elements, such as IoTs, CPSs, BDA, ML, BCT, CC, and collaborative robots [62]. Here, the newly developed concept, digital triad (DT-II), is used to represent an abstract system element of SM [3,4]. DT-II is an extension of the concept of digital twins (DT-I), and DT-II includes the enablers to meet the functional requirements FR1, FR2, FR3, FR4, and FR5 that were discussed in Section 3.2. As shown in Figure 2, a digital triad

(DT-II) is a coalition of life models, digital models, and the corresponding physical models.

Accordingly, DT-II is modelled by three models and their interactions as,

DT − II(t) = {LM(t), DM(t), PM(t), CN(LM(t), DM(t), PM(t), t), ET(t)} t = t1 , t2, . . . tn, . . . (1) where DT-II (t) represents the state of a digital triad at time t, LM(t), DM(t), andPM(t) are

the sets of life, digital, and physical models at t, respectively; CN(LM(t), DM(t), PM(t), t) are the interactions of life, digital, and physical models at t; ET(t) is the set of enablers for the operations of DT-II; t1, t2, t3, . . . are timeframes to update DT-II.

In a DT-II model, a physical model PM(t) represents one, or a group of, physical thing(s), such as the parts, products, processes, systems, or other tangible things, and a digital model DM(t) is a virtual model of PM(t). One physical model PM(t) may need multiple DM(t) to represent its behaviors from different perspectives. A life model LM(t) represents the changes of physical things over time; it keeps historical data, components, templates, and knowledge that are used to design, analyze, optimize, and reconfigure the physical models. The interactions of the three models, PM(t), DM(t), and LM(t), are represented by CN(LM(t), DM(t), PM(t), t). There are three types of interactions

CN(LM(t), DM(t), PM(t), t) in DT-II, (i.e., CN,1(DM(t), PM(t)), CN,2(LM(t), DM(t), t), and CN,3(LM(t), PM(t), t)). In addition, a particular DT-II model can be instantiated by specifying a set of enablers ET(t) to create, operate, and sustain the models. As discussed in Section 2.3, the most commonly mentioned enablers in ET(t) are IoT, CC, AI, CPS, ML, BDA, BCT, machine learning (ML), reference models, standardizations, and edge technologies.

The proposed DT-II serves as a modelling solution to FR1, FR2, FR3, FR4, and FR5 of a smart manufacturing system at the element level as,

![]()

![]()

![]() FR}E {MS}E

FR}E {MS}E

{

M

![]() FR1

FR1

FR3 = × × C (t)

FR4 ⎪⎪⎪ ⎢⎣ × × C (t)

FR5 ⎪⎭ × × × × C (t)

E (t)

wheretions at the element level, respectively;{FR}E and {MS}E are the set of functional requirements (FR) and modelling solu-{MR}E is a matrix for mapping from {MS}E and

![]() E ” represent a

closely and loosely relevant mapping, respectively.

E ” represent a

closely and loosely relevant mapping, respectively.

3.4. Internet of Digital Triad Things (IoDTT) as a Reference Model

A smart manufacturing system is, in fact, a system of systems (SoS). Despite the distributed, decentralized, and heterogeneous nature of system elements, an abstract element model based on DT-II can only represent the characteristics at the element level, rather than all system characteristics, including the needs for accessing virtual resources and reconfiguring systems over time.

It should be noted that the existing reference models are highly diversified and lack the generality required for users to understand, analyze, engineer, improve, optimize, manage, control, and maintain the systems in specific applications. System models are fundamental to enterprise engineering, integration, and management [63]. A reference SM model should support (1) the integration of the data, knowledge, and wisdom of all stakeholders, from suppliers to users, (2) the evaluation of system options based on high-level performance indicators (KPIs), (3) the adaptation to dynamic changes and uncertainties, (4) the seamless connection of information technology infrastructure, and (5) the affordable cost of modelling, simulation, and data analytics [25]. A reference model traditionally consists of multiple views to look at the transformation of manufacturing businesses from different views. For example, Vernadat [63] included functional, business, organizational, information, infrastructural, product, economic, and collaboration views as the main facets of a reference model. Essakly et al. [64] developed a reference framework to evaluate digitalization solutions for SMEs. The impact of technology adoption was assessed across 16 main fields of action. Moghaddam et al. [65] discussed the existing works on the development of reference SM models; popular reference SM architectures include Reference Architectural Model Industrie 4.0 (RAMI4.0), the Industrial Internet Reference

Architecture (IIRA), IBM Industry 4.0, and NIST smart manufacturing. These architectures were service-oriented and the manufacturing assets were digitized and integrated as ondemand services, and SM enabled the collaboration and integration of manufacturing assets via smart plug-and-produce systems. Yang et al. [66] argued that the main objective of SM is to improve the flexibility and adaptability of manufacturing systems; therefore, SM should be data-driven and should support knowledge-based engineering. The reference SM model created by Part and Febriani [67] for welding operations was service-oriented, since virtual manufacturing assets became mandatory for dealing with the ever-growing complexity, scale, and system dynamics.

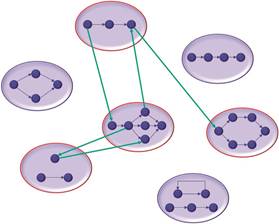

To model the interaction of system elements in SM, the concept of the Internet of Digital Triad Things (IoDTT), developed by the authors, is introduced here. Figure 3 illustrates a representation of IoDTT for SM. A smart manufacturing system is developed upon an information infrastructure {ET(t)} that consists of all of the accessible tools to acquire, process, mine, and utilize data regarding the system elements for decision making support. IoDTT uses a flat architecture in which all of the system elements {DT-II (t)} are networked and interact. Each DT-II (t) is reconfigurable to sustain its lifecycle, and the lifecycle of SM is represented as a series of (SoS (t) at specific times. A smart manufacturing system, at a specific time ti, is formed by one host digital triad DT-IIh (ti) with selected others. The life model Lm,h (ti) of the host digital triad selects a set of appropriate digital triads and constructs them as a system of systems (SoS (ti)). The digital and physical models, Dm,h (ti) and Pm,h (ti), are upgraded to adapt to the changes resulting from their interactions with others.

Figure 3. Internet of Digital Triad Things (IoDTT) as reference model for SM.

The proposed IoDTT serves as the modelling solution to FR6 and FR7 of a smart manufacturing system at the SoS level as,

![]()

![]() {FR} ⎧ {{FRFR}}S ⎫ {MR{}MRE }S {MS}S

{FR} ⎧ {{FRFR}}S ⎫ {MR{}MRE }S {MS}S

{FR}N FR7 ⎩

whereand modelling solutions determined in Equation (1) at the element level; {{FR}E, {MR}E, and {MS}E are the functional requirements, mapping relations,FR}N = {FR6,

FR7}T are the functional requirements at the system level; {SoS(t)} is a set of system configurations in the system lifecycle; {ET(t)} is the information infrastructure including all of the accessible enabling technologies. “×” and “” represent a closely and loosely relevant mapping, respectively.

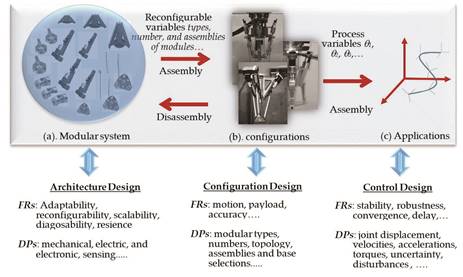

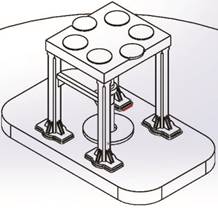

The designs involved in a modular robotic system in Figure 4 were used to illustrate the applications of an ad hoc approach to designing and implementing a smart manufacturing system, and to elaborate the need for developing a generic design methodology for the design of smart manufacturing systems.

Figure 4. Example of designing and implementing a smart manufacturing system using an ad hoc approach (Reprinted with permission from ref. [4]. 2021, Springer Nature).

Robots play increasingly critical roles in modern manufacturing [62,68]. However, conventional robots were sophisticated and applicable only to specific types of tasks. Robots in SM should be advanced to reconfigure themselves, both in hardware and software aspects, so that the same system can be applied to different types of tasks in uncertain environments. As shown in Figure 4a, the architecture of a smart robotic system is modularized; it consists of various types of functional modules, rather than an integral robotic structure. Different modules can be selected and assembled in different ways to build different configurations for given tasks over time. Similar to the designs of other complex systems, ad hoc approaches are used in designing and implementing a modular robotic system. The three main design issues are architecture design, configuration design, and control design [69,70]. Architecture design determines the available functional modules and their possible interfaces. The design of a functional module is encapsulated, and the internal change of one module does not affect its interaction with other modules. A system’s architecture must offer as many configuration variants as possible, subjected to a given pool of available modules. The more configurations a system can generate, the better the system can deal with changing tasks in a dynamic environment. Architecture design is also involved in upgrading a smart system. Configuration design involves the selection and assembly of modules in a robot instance to optimally perform a given task. An active module has its local controller, an assembled robot has its system-level goals, and the control is designed to coordinate system modules to fulfill system-level tasks satisfactorily. Control design is involved during the phase of system operation.

Several research teams worldwide have contributed to the design theories and methodologies of modular robotic systems. However, every group emphasized the specialties of their proposed systems, and these systems are designed and implemented in ad hoc ways in general. Bi and Lang [69] and Bi et al. [70] discussed the limitations of ad hoc system approaches, including repetitive design efforts, inconsistency in system upgradations, the difficulty in scaling systems, and, most importantly, the lack of predictivity for future technologies to maintain the sustainability of a smart system.

It seems that any complex system, including a smart manufacturing system, should be customized to its specific application; the design of a smart manufacturing system is carried out on a case-by-case basis. However, a smart manufacturing system emphasizes its continuity from one system configuration to another to achieve adaptability and sustainability over time. The authors argue that it is critical to investigate the commonalities of different smart systems, since a general design methodology addressing the identified commonalities will help to significantly alleviate the aforementioned challenges.

It should be noted that any system design can be viewed as a transformation from the given inputs to the expected outputs, and different smart manufacturing systems share many commonalities in such a transformation. While the implementation of a specific system deals with the definitions of customers’ needs and the expected outputs that are specialized, many commonalities can be identified. Taking the example of smart manufacturing systems: (1) customer requirements share the commonalities of the quantification of adaptability, resilience, and configurability; (2) the expected system designs share the commonalities of digitization, modularization, and high levels of automation and autonomy; (3) the design transformations share time-dependence, dynamics, concurrence, and continuous improvement. Therefore, the generality of a design methodology and the specialty of system implementation are not conflicted with each other. While a generic design methodology cannot be used to substitute all of the design efforts in defining quantifiable functional requirements, system measures, and modelling system behaviors to evaluate design solutions, following the generic guidance and design procedure will help users to reduce repetitive efforts, achieve consistency for system upgradation, enhance system scalability, and increase the visibility of prosperous technologies for long-term system sustainability.

To promote the application of digital technologies in manufacturing, particularly for small and medium sized companies, and for continuous improvement practice, we aimed to develop a generic methodology for the design of smart manufacturing systems. A concise definition of smart manufacturing (SM) was provided (based on the newly developed concepts of digital triad (DT-II) and Internet of Digital Triad Things (IoDTT), which covers the common requirements and enabling digital technologies of various manufacturing systems that are customized for specific applications. Axiomatic design theory was proposed to formulate system designs, or to reconfigure systems into mathematic models by defining the functional requirements (FRs), identifying the feasible design solutions (DSs), and evaluating system smartness based on the mapping of FRs and DSs. It should be noted that ADT is widely adopted as a systematic design approach in designing complex systems [71,72]. Part II of this paper will provide the details of ADT applications in the design of smart manufacturing, and three case studies will be introduced to demonstrate the generality and applicability of using the proposed method for designing smart manufacturing systems. The proposed concepts have theoretical and practical significance for exploring the essentials of different smart manufacturing systems, so that a systematic design methodology can be developed to guide the design of smart manufacturing systems with diversified applications. It should be noted that the proposed concepts and design methods are generic, and are used as the systematic guides in designing and analyzing a smart manufacturing system. However, every manufacturing system must be customized to its specific applications, and additional design effort is required to prioritize FRs, identify the pool of DSs, and develop performance metrics for the appropriate mapping of FRs and DSs when using the proposed concepts and design methods.

Author Contributions: Conceptualization, Z.B. and W.-J.Z.; methodology, Z.B. and C.W.; background study, C.L., L.X. and Z.B.; formal analysis, W.-J.Z., C.L., L.X.; investigation, Z.B., W.-J.Z., C.W., C.L. and L.X.; writing—original draft preparation, Z.B.; writing—review and editing, W.-J.Z., C.W., C.L. and L.X. All authors have contributed substantially to the report and they have read and agreed to the published version of the manuscript.

Funding: This research received no external funding.

Institutional Review Board Statement: Not applicable.

Informed Consent Statement: Not applicable.