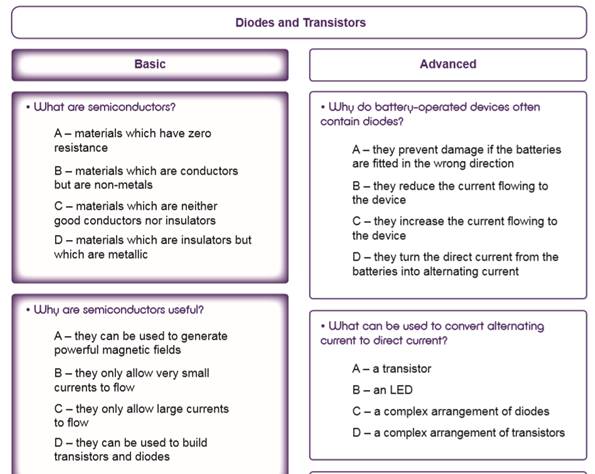

MULTICPLE CHOICE QUESTIONS: DIODES AND TRANSISTORS

READING TASK: THE SEMI-CONDUCTOR DIODE

The p-n junction

If a region of p-type material and a region of n-type material are

formed side by side in a piece of silicon, a p-n junction is formed. It is

important that this is made in one piece of the material so that the crystal

lattice extends across the boundary. It is not sufficient just to have two

pieces in contact.

If a region of p-type material and a region of n-type material are

formed side by side in a piece of silicon, a p-n junction is formed. It is

important that this is made in one piece of the material so that the crystal

lattice extends across the boundary. It is not sufficient just to have two

pieces in contact.

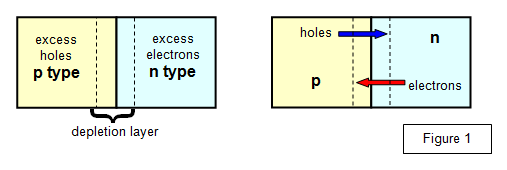

Both the p-type and the n-type material are electrically neutral, but they both

contain an imbalance of conduction electrons or holes. At the boundary, holes

drift from the p-type towards the n-type material and electrons drift from the

n-type to the p-type to reduce this imbalance. This diffusion of holes and

electrons across the boundary sets up a potential barrier which prevents

further change, the p-type region becoming slightly negative and the n-type

becoming slightly positive. The barrier has a potential difference across it of

about 0.1 V, although the exact size of the potential barrier depends on the

material. These effects only occur over a very small region (about 10-3 mm

on either side of the boundary) known as the depletion layer. They are

summarised in Figure 1.

The p-n junction forms a semiconductor diode. If current is to

flow through the diode, then the latter must be connected in a circuit in such

a way as to reduce the height of the potential barrier, that is, the p-type

material must be made positive to attract more electrons and the n-type must be

made negative.

The p-n junction forms a semiconductor diode. If current is to

flow through the diode, then the latter must be connected in a circuit in such

a way as to reduce the height of the potential barrier, that is, the p-type

material must be made positive to attract more electrons and the n-type must be

made negative.

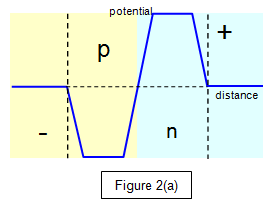

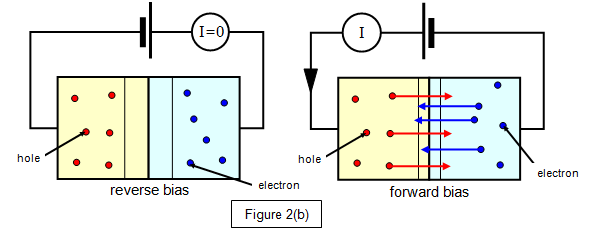

Connecting it in such a way is called forward bias, and round the other way is

known as reverse bias. A reverse bias tends to increase the width of the

depletion layer while a forward bias will reduce the width of this layer (see

Figure 2).

Characteristics of a p-n junction diode

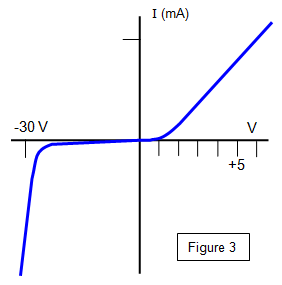

The characteristics of a germanium junction diode are shown in

Figure 3. When in the forward biased direction the current increases almost

linearly as the potential difference across it is increased, a potential difference

of a volt giving a current of a few milliamps. In the reverse direction the

current is only a few microamps until the diode breaks down, this occuring at a

reverse potential difference of some 30V.

The characteristics of a germanium junction diode are shown in

Figure 3. When in the forward biased direction the current increases almost

linearly as the potential difference across it is increased, a potential difference

of a volt giving a current of a few milliamps. In the reverse direction the

current is only a few microamps until the diode breaks down, this occuring at a

reverse potential difference of some 30V.

Diodes must be protected from excess temperature, otherwise their structure

will be destroyed. The limit for germanium is about 100 oC, and

that for silicon about 200 oC.

Semiconductor diodes have several advantages over thermionic diode valves. They

are smaller, require less voltage to operate, do not waste so much energy as

heat and are quick and cheap to manufacture.

THE LIGHT EMITTING DIODE (LED)

The LED is likely to be the

most important advance in lighting in the early part of the twenty first

century. LEDs used to be available as low power indicators in two types – one

that emitted  red light and the other that emitted green light.

red light and the other that emitted green light.

The big advance was the development of relatively high power LEDs that emitted white light. I have a torch that contains five LEDs that gives a total output of 15000 mcd (power consumption 0.6W) using a current of 150 mA at between 3 and 3.5V.

To understand how the LED works it is important to understand the

workings of the semiconductor diode – see: Semiconductor diode

It is very likely that all homes

will eventually be lit by LED light sources. They consume low power, are small,

fairly robust, emit virtually no heat energy and give a good clear white light.

Just like a normal semiconductor diode current flows when electrons move from

the conduction band in the n type cathode" to the valance level in the p

type "anode". The difference is that with the LED when the electron

falls into a positive hole energy is released in the form of a photon. The

wavelength of this photon depends on the energy gap of the materials of the p-n

junction.

White light emitting LEDs can be made in a variety of ways. One is to coat a

blue emitting LED with a material that converts some of the blue light to

yellow. The yellow light stimulates both the red and green receptors in the

eye. When this yellow light is combine the original blue emitted by the LED the

resulting output gives the impression of white light.

THERMISTOR

This is a type of resistor is made from a sintered semiconductor

material which has a resistance that changes with temperature. There are two types of

thermistor:

This is a type of resistor is made from a sintered semiconductor

material which has a resistance that changes with temperature. There are two types of

thermistor:

(i) negative temperature coefficient (NTC) – the resistance of the thermistor

falls with increasing temperature

(ii) positive temperature coefficient (PTC) - the resistance of the thermistor

rises with increasing temperature

The NTC is the type most often used in schools so I will just consider that

type in detail.

The increasing temperature produces more free electrons and so the resistance

falls. These electrons are able to 'jump' from the valence band to the

conduction band. This increase in conduction electrons masks the effect due to

the increase thermal motion of the atoms and electrons.

At low temperature its resistance is large (thousands of ohms), at high

temperature its resistance is small (tens of ohms). Very little current will

flow through it when it is cold. This means that its resistance increases as

the temperature falls.

A graph for the thermistor of resistance against its temperature is shown in

Figure 1.

You can investigate this property practically by doing the experiment described

in the 14-16 Experiment guides called Thermistor resistance.

Uses of thermistors (NTC)

Thermistors

are used as temperature sensors in thermostats in ovens and irons, in fire

alarms and on the wing of a plane to detect when the temperature falls low

enough for ice to form. They are also in use in premature baby units to detect

when a baby may have stopped breathing, current limiting devices and

thermometers.

(Sintering is a process where particles of the

material are heated below their melting point until they stick together)

Скачано с www.znanio.ru

Материалы на данной страницы взяты из открытых источников либо размещены пользователем в соответствии с договором-офертой сайта. Вы можете сообщить о нарушении.